A desktop SMT reflow oven is a compact, high-precision device designed for small-scale electronics production and prototyping. Equipped with advanced PID temperature control and forced hot-air convection systems, it ensures uniform heating across 3-6 zones, achieving ±1°C accuracy . The process begins with programmable preheat, soak, reflow, and cooling stages, allowing users to customize temperature profiles for lead or lead-free solder pastes . Key features include a built-in smoke filtration system for safe operation, RS-232/WiFi connectivity for remote monitoring, and a compact design that fits on lab benches . Modern models integrate infrared and convection heating to reduce thermal stress on PCBs while supporting up to 300°C peak temperatures . Ideal for R&D labs, educational institutions, and small manufacturers, these ovens handle PCB sizes up to 350x250mm and ensure reliable solder joints with minimal oxidation, even in nitrogen environments . With energy-efficient operation (1.2-2kW) and user-friendly interfaces, they balance cost-effectiveness with industrial-grade performance.

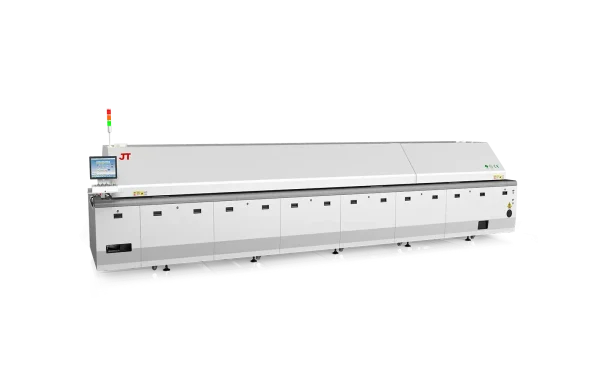

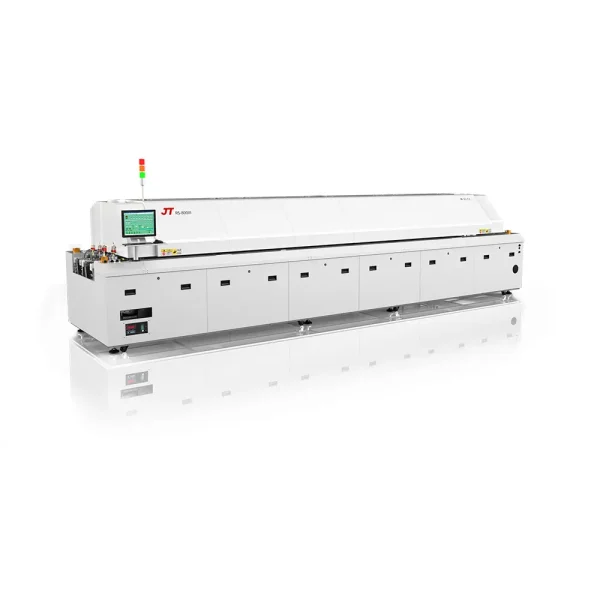

| MODEL | RS-600III/RS-600III-N |

| GENERAL | |

| Outside Dimension(L*W*H) | 4190 x 1430 x 1530mm |

| Weight | Approx. 1850KG/1950KG |

| Number Of Heating Zones | Up 6 / Bottom 6 |

| Length Of Heating Zones | 2295mm |

| Number Of Cooling Zones | Up 1 / Bottom 1 (Cool Air Conversion) |

| Exhaust Volume | 10 m³ / min x 2 (Exhausts) |

| Control System | |

| Electric Supply Required | 3 phase, 380V 50/60Hz (Optional: 3 phase, 400V/480V 50/60Hz ) |

| Electric Power Required | 48KW / 51KW |

| Power For Warm Up | 24KW / 26KW |

| Power Consumption | 6.5KW / 7KW |

| Warming Time | Approx. 20 minute |

| Temp. Setting Range | Room Temp. — 300℃ |

| Temperature Control Method | PID Close Loop Control + SSR Driving |

| Temperature Control Precision | ± 1.0℃ |

| Temperature Deviation on PCB | ± 1.5℃ (by JT Board Test Standard) |

| Commutated Element | Aluminium Alloy Plate |

| Data Storage | Various prameters and status are storable (80GB) |

| Abnormal Alarm | Abnormal Temperature (Extra-high / Extra-low Temp.) |

| Board Dropped Alarm | Tower Light: Yellow–Warming; Green-Normal; Red-Abnormal |

| Conveyor System | |

| Rail Structure | Subsection Integrated Type (Option : Subsection Separate Control) |

| Max.Width Of PCB | 400mm (OPTION :460mm) |

| Range Of Rail Width/Adjustment | 50~400mm / Motorized |

| Components Clearance | PCB Top 30mm/ Bottom 25mm |

| Converyor Direction | L→R (Option: R→L) |

| Fixed Rail Side | Front Rail Fixed (Option:Rear Rail Fixed) |

| PCB Transmission Agent | Air-Reflow =Chain + Mesh , ( N2-Reflow = Chain only and Mesh optional) |

| Converyor Height | 900±20mm |

| Converyor Speed Range | 300~2000mm/min |

| Lubrication Auto-Afflux | Standard |

| Cooling System | |

| Cooling Method | Standard:Forced-Air Type |

Notes: D:Dual rails,Fixed mode is optional,the max width of PCB is 250*250mm;N:Nitrogen;L:the max width of PCB is 610mm

The above contents are subiect to change without further notice.