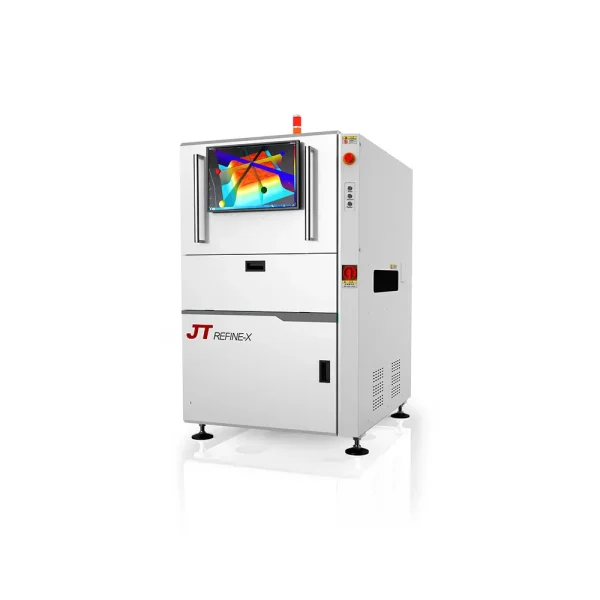

| Model | JTA-660B | |

| PCB Spec. | PCB Dimension | 50x50mm – 430x460mm |

| PCB Thickness | 0.5mm – 5mm(Standard) (5~20mm Customized) | |

| PCB Component height | Top 110mm Bottom 25mm | |

| PCB Warp | ±3mm | |

| Optical Parameter |

Resolution | 23μm(Standard) |

| Speed | 0.25 sec/FOV | |

| Camera Spec. | 5M High Speed Color Camera | |

| Optical Lens | Telecentric Optical Lens | |

| Light-Source | Multis pectral Super speed RGB+W Light Source | |

| Inspection Category | Component Inspection | ꢀMissing,ꢀRolling,Shifting,Polarity Error,Wrong Part,Damaged,Bended,PCB Abnormal,Residua,Glue Overflow |

| Solder Inspection | Excess Solder, Insufficient Solder,Bridging,Lifting,Solder Balls,Soldering Abnormal | |

| Special Inspection Items | Can Check Solder Paste and Epoxy Glue Process, Soldering Quality | |

| Hardware | X,Y Table Positioning Accuracy | ±0.01mm |

| X,Y Table Speed | 1000mm/s | |

| PCB Loading | Defined Mode: R->L / L->R | |

| PCB width adjustment | AUTO | |

| Main Frame Body | Whole Cast Iron Modeling | |

| Screwing-shaft | High precision ball screw | |

| Rail | High Level Rail | |

| Driver | AC Servo Motor | |

| OperatingSystem | Win 7 Professional | |

| Display | 22” LCD Monitor | |

| PowerSupply | AC 200-240V1Φ 50/60HZ | |

| Power | 1.8KW | |

| Pressure | 0.5MPa | |

| Dimension (W*D*H) | 1039x1483x1550mm | |

| Weight (KG) | 1000KG +/- 10KG | |

| Software | InspectionMethod | The Eigenvector Analysis & OCV Silkscreen Algorithm |

| InspectionAngleArea | 0-360°,Accuracy=1° | |

| MarkingFunction | One Board Marking & Multi-pieces Board Marking & Bad Marking, etc. | |

| ProgrammingMode | 1.CAD Coordinate Loading 2.Component Database Auto-index 3.Auto-programmingby Intelligent Software |

|

| RemoteControl | Network Monitoring: Offline Debugging, Online Monitoring & Manipulating, Remote Realized Examing | |

| DataRecording | Auto-generated Statistical Process Controlling Data (SPC) & Report | |

| Option | Barcode Scanner 1D/2Dꢀ(H/W) | Pin Support |

| Quality Tracing (Option) | Offline Programming System (PC) | |

| Three-point-verification System (Option) | 1D/2D Barcode Reading (S/W + License) | |

| The above contents are subject to change without further notice! | ||

Solder Joint and Component Inspection AOI JTA-660B

JTA-660B Intro:

● China’s first DIP process online AOI.

● Inspection after soldering without turning over PCB.

● High speed Inspection: Fully satisfied DIP production.

● It can reduce manpower greatly.

● Intellectual self-repairing technology: Connectable to soldering robot.

JTA-660B Intro:

● Simultaneous Inspection for both sides of PCB during DIP in-process SMT & DIP Component.

● High depth of field optical system.

● High speed Inspection: Fully satisfied DIP production.

● It can reduce manpower greatly.