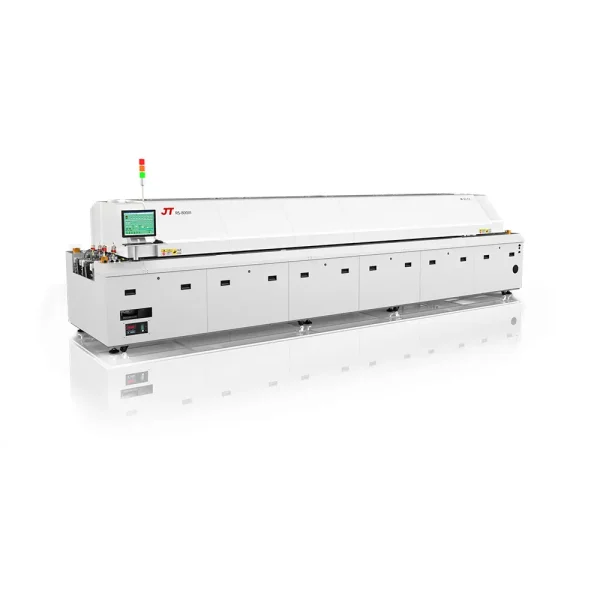

| Model No. | VLO-730 |

| Dimension (L*W*H) | 1980X1750X2250 mm |

| Min PCB dimension | 90X90 mm |

| Max PCB dimension | 300X350 mm |

| PCB Stacking Spacing | 25.4 mm |

| Max. Quantity of PCB Storing | 70PCS |

| Converyor Height | 900±20 mm |

| Cycle Time | ≥10S |

| PCB Direction | L→R or R→L |

| Guide rails Parallelism | <±0.8mm |

| Guide rail Adjustment | Electric/Manual |

| Device Configuration | |

| Temperature Setting range | RT ~200 ℃ |

| Temperature Control mode | PID closed-loop control +SSR drive. |

| Temperature Accuracy | ±1℃ |

| Temperature Uniformity | △T≤3℃ |

| The number of heating zones. | 6 |

| HeatingꢀupꢀTime | <30Min |

| Blower Speed | Variable Speed Control |

| Control System | |

| Power | 3Φ AC380V/ 50/60HZ(3Φ220V 50/60HZ Subject to technical agreement) |

| Total Power | 65 KVA |

| Normal Working Consumption | 4~6KW |

| SmemaꢀPort | In /out |

| UPS | Std. |

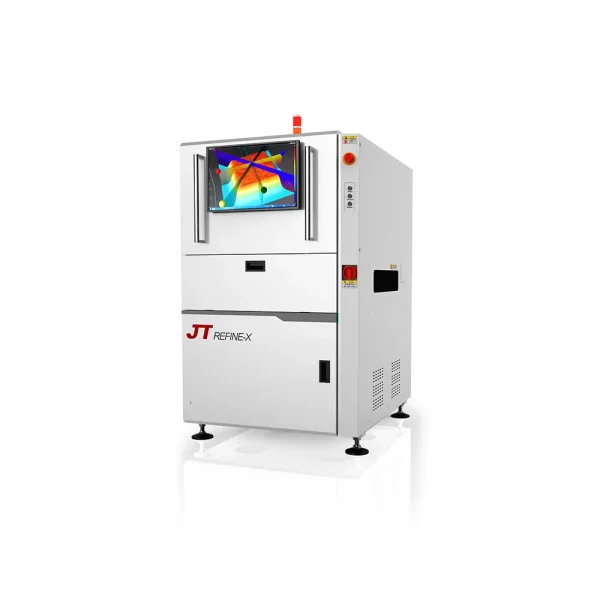

VLO Series Vertical Curing Oven

● The in-line vertical curing oven has the characteristics of compact in size, high production efficiency, and low energy consumption, which greatly improves the utilization rate of the production plant, and this is a new trend of development of the oven in the future.

● Very good thermal efficiency can be fully qualified for the product heating and curing of various specifications, to ensure the perfect curing quality.

● In-Line automated production, Save labor cost.

● Cycle time is adjustable. Suitable for various curing process.

● Reinforce thermal insulation structure, the surface temperature is higher about10°C than the room temp, to reduce the influence of the working environment.

● Six-zone heating, flexible for setting.

● Vertical lifting structure, save space greatly, improve the utilizationrate of factory.

● Optional nitrogen system.