Reflow oven machines operate through precise thermal management across four critical phases: preheating (ramp-up), soaking (thermal stabilization), reflow (peak temperature), and cooling. The system employs multi-zone heating elements with PID-controlled forced convection to achieve ±1°C temperature uniformity. During reflow, solder paste reaches its liquidus state (typically 217-250°C for lead-free alloys), forming metallurgical bonds while flux removes oxides. Advanced systems integrate thermocouple feedback loops and nitrogen inerting to optimize wetting angles and prevent void formation. This controlled thermal profiling ensures reliable intermetallic compound formation without component thermal shock, meeting IPC Class 3 standards for high-reliability electronics.

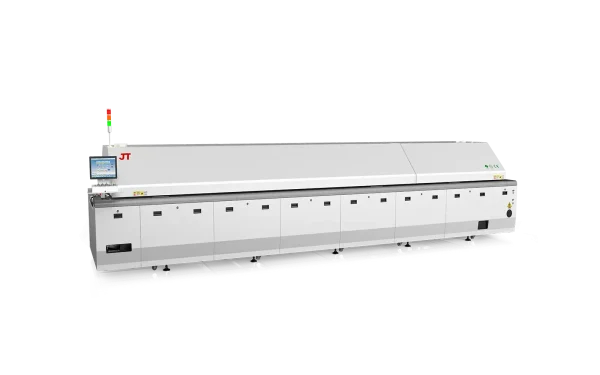

| MODEL | RS-600III/RS-600III-N |

| GENERAL | |

| Outside Dimension(L*W*H) | 4190 x 1430 x 1530mm |

| Weight | Approx. 1850KG/1950KG |

| Number Of Heating Zones | Up 6 / Bottom 6 |

| Length Of Heating Zones | 2295mm |

| Number Of Cooling Zones | Up 1 / Bottom 1 (Cool Air Conversion) |

| Exhaust Volume | 10 m³ / min x 2 (Exhausts) |

| Control System | |

| Electric Supply Required | 3 phase, 380V 50/60Hz (Optional: 3 phase, 400V/480V 50/60Hz ) |

| Electric Power Required | 48KW / 51KW |

| Power For Warm Up | 24KW / 26KW |

| Power Consumption | 6.5KW / 7KW |

| Warming Time | Approx. 20 minute |

| Temp. Setting Range | Room Temp. — 300℃ |

| Temperature Control Method | PID Close Loop Control + SSR Driving |

| Temperature Control Precision | ± 1.0℃ |

| Temperature Deviation on PCB | ± 1.5℃ (by JT Board Test Standard) |

| Commutated Element | Aluminium Alloy Plate |

| Data Storage | Various prameters and status are storable (80GB) |

| Abnormal Alarm | Abnormal Temperature (Extra-high / Extra-low Temp.) |

| Board Dropped Alarm | Tower Light: Yellow–Warming; Green-Normal; Red-Abnormal |

| Conveyor System | |

| Rail Structure | Subsection Integrated Type (Option : Subsection Separate Control) |

| Max.Width Of PCB | 400mm (OPTION :460mm) |

| Range Of Rail Width/Adjustment | 50~400mm / Motorized |

| Components Clearance | PCB Top 30mm/ Bottom 25mm |

| Converyor Direction | L→R (Option: R→L) |

| Fixed Rail Side | Front Rail Fixed (Option:Rear Rail Fixed) |

| PCB Transmission Agent | Air-Reflow =Chain + Mesh , ( N2-Reflow = Chain only and Mesh optional) |

| Converyor Height | 900±20mm |

| Converyor Speed Range | 300~2000mm/min |

| Lubrication Auto-Afflux | Standard |

| Cooling System | |

| Cooling Method | Standard:Forced-Air Type |

Notes: D:Dual rails,Fixed mode is optional,the max width of PCB is 250*250mm;N:Nitrogen;L:the max width of PCB is 610mm

The above contents are subiect to change without further notice.