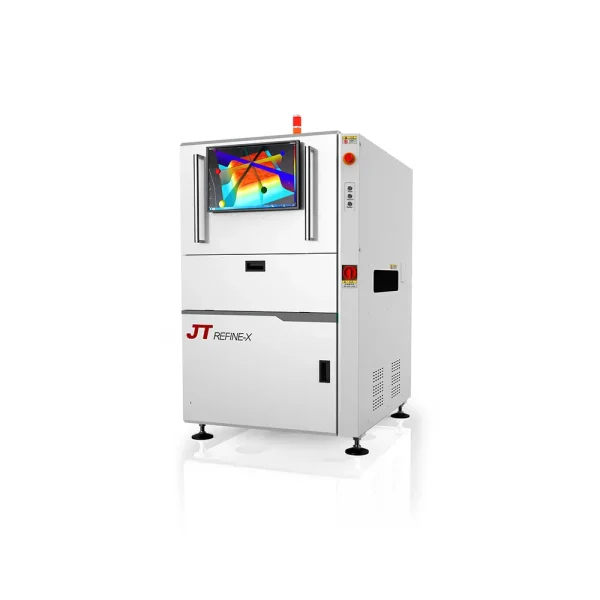

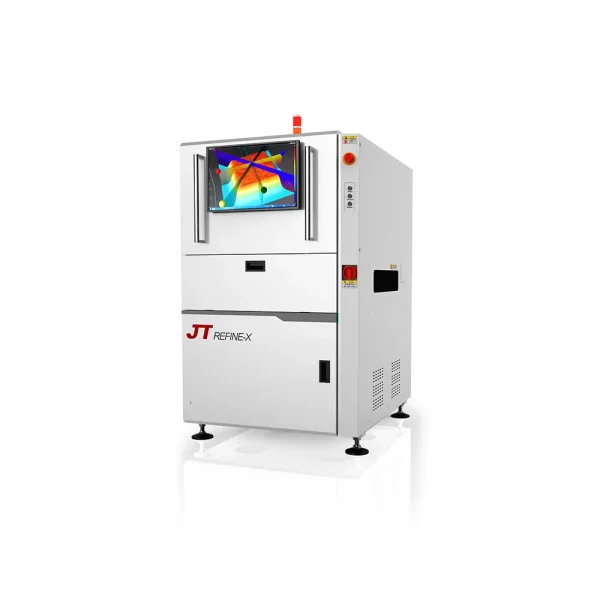

| Model | JTA-JUTI-X | |

| PCB Spec. | PCB Dimension | 50x50mm – 440x480mm |

| PCB Thickness | 0.5mm – 5mm(Standard) | |

| PCB Component height | Top 25mm Bottom 50mm | |

| PCB Warp | ±3mm | |

| Optical Parameter |

Resolution | 15μm(Standard) 10μm/12μm,Option |

| Speed | 0.25 sec/FOV | |

| Camera Spec. | 5M High Speed Color Camera | |

| Optical Lens | Telecentric Optical Lens | |

| Light-Source | Multis pectral Super speed RGB+W Light Source | |

| Inspection Category | Component Inspection | Missing, Rolling, Shifting,Polarity Error,Wrong Part, Damaged, Bended,PCB Abnormal, Residua, Glue Overflow |

| Solder Inspection | Excess Solder, Insufficient Solder,Bridging,Lifting,Solder Balls,Soldering Abnormal | |

| Special Inspection Items | Can Check Solder Paste and Epoxy Glue Process, Soldering Quality; Checking Floating Componebts Cold Joint by 3D | |

| Hardware | X,Y Table Positioning Accuracy | ±0.01mm |

| X,Y Table Speed | 1000mm/s | |

| PCB Loading | Defined Mode: R->L / L->R,L->L,R->R (Standard) | |

| PCB width adjustment | By AUTO + By Manual (Standard) | |

| Main Frame Body | Whole Cast Iron | |

| Screwing-shaft | High precision ball screw | |

| Rail | High Level Rail | |

| Driver | AC Servo Motor | |

| OperatingSystem | Win 7 Professional | |

| Display | 22” LCDs | |

| PowerSupply | AC 200-240V1Φ 50/60HZ Single-phase | |

| Power | 1.7KW | |

| Pressure | 0.5MPa | |

| Dimension (W*D*H) | 947x1321x1547mm | |

| Weight (KG) | 1050KG+/-10KG | |

| Software | InspectionMethod | The Eigenvector Analysis & OCV Silkscreen Algorithm |

| InspectionAngleArea | 0-360°,Accuracy=1° | |

| MarkingFunction | One Board Marking & Multi-pieces Board Marking & Bad Marking, etc. | |

| ProgrammingMode | 1.CAD Coordinate Loading 2.Component Database Auto-index 3.Auto-programmingby Intelligent Software |

|

| RemoteControl | Network Monitoring: Offline Debugging, Online Monitoring & Manipulating, Remote Realized Examing | |

| DataRecording | Auto-generated Statistical Process Controlling Data (SPC) & Report | |

| Option | Barcode Scanner 1D/2D (H/W) | |

| Quality Tracing (Option) | Offline Programming System (PC) | |

| Three-point-verification System (Option) | 1D/2D Barcode Reading (S/W + License) | |

| The above contents are subject to change without further notice! | ||

Solder Joint and Component Inspection AOI JUTI

JUTI-X Intro:

● High cost performance in line AOI

● 5 Mega-pixel high-speed camera

● Resolution 10um (12um,15um is option)

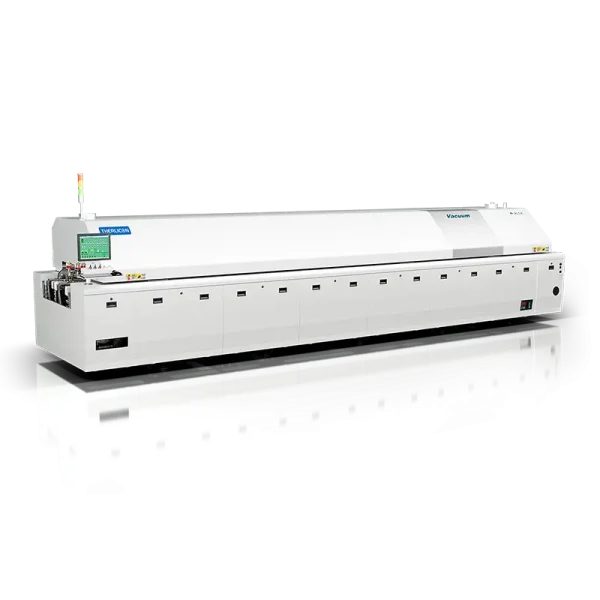

JTA-JUTI-MX Intro:

● Super speed, high-precision

● High resolution

● FPC special detection logic

● Message communication between front and rear of oven

● Defect analysis

● Professional SPC data analysis and processing

● Centralized management, reduce manpower

● Multiple machines remote debugging and program updates

● Optional dual-rail

JTA-JUTI-DX Intro:

● Special detection logic for smart phone

● Equipment compatibility, message communication

● Super speed, high-precision, high resolution

● Analysis of defective process

● SPC data analysis and processing

● Centralized management, reduce manpower

● Multiple machines remote debugging and program updates