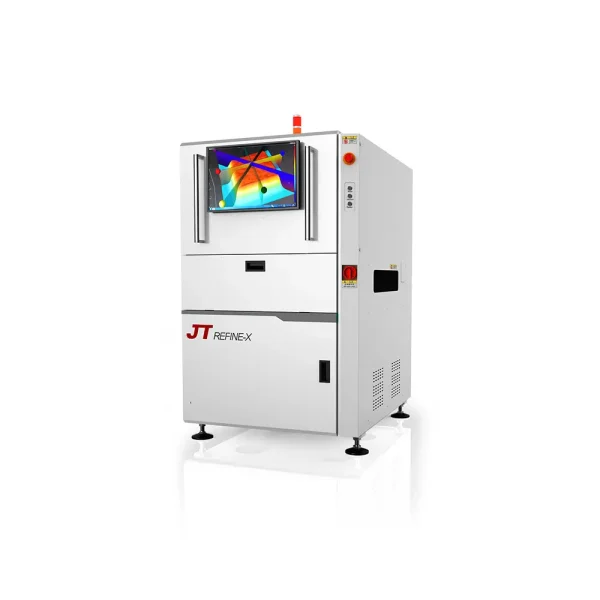

SPI is a critical quality control step in the SMT manufacturing process. It uses advanced imaging or laser technology to inspect solder paste applied to PCB pads. Inspectors verify the amount, placement, and uniformity of the solder paste, and detect defects such as insufficient solder paste, misalignment, or bridging. By detecting problems early, SPI inspection can prevent soldering failures, ensure reliable component bonding, and improve the overall production quality of electronic assemblies.

| Model | REFINE-XS |

| Inspection Module | |

| Camera Specification | 5M High-frequency Industrial Camera, High Frame Number (Factory Setting); 12M Option |

| Pixel | 20μm, 15μmꢀ(Factory Setting) |

| FOV(single field of view) Range | 40×40 mm, 30×30 mm (Factory Setting) |

| LED | RGB + TOP |

| Light Source | 0 – 550 μm |

| Height Inspection Resolution | 0.36 μm |

| Height Inspection Accuracy | 1μm (Based on the actual solder paste/calibration block) |

| Inspection Item | Volume, Area, Height, X/Y Position, Bridging, Shape, etc |

| Defective Type | Excessive/Insufficient/Missing paste,Bridge,2D & 3D Paste displacement, Shape deformity, Dust, etc |

| Repeatability (Volume, Area, Height) | <1% @3sigma |

| GR & R (Gauge Reproducebility and Repeatability) | < 10% (@6sigma tolerance = +/- 50%) |

| Inspection Speed | 0.35Sec / FOV |

| Conveyor & PCB Size | |

| Max PCB Size | 460×410 mm |

| Min PCB Size | 50×50 mm |

| PCB Up-Clearance | 30 mm |

| PCB Bottom-Clearance | 30 mm |

| PCB Thickness | 0.5-5 mm |

| Max PCB Warpage | ±3 mm |

| PCB Transfer Height | 2.5mm |

| PCB Transfer Height | 900±20 mm |

| Max PCB Weight | 5KG |

| Frame & Others | |

| Base & Frame | Integra1 steel casmting frame; firmly, ensure high accuracy of inspection |

| Dimensions and Weight | 947x1321x1600mm (W x D x H) 950KG |

| Power Supply | AC 220V 1Φ 50/60Hz |

| Power | 2.2KW |

| Communication Interface | SMEMA |

| Air Supply | 4-6bar,5L/min |

| Operating Condition | 5-40℃, 15-90% RH |

| Options | |

| 1. BarcodeReader | 4. Repair Station (PC) |

| 2. 3D Calibration Target | 5. Infared Muti-touch LCD + Voice Control |

| 3. 2D Calibration Glass | 6. Offline Editing Software (License Key) |

| The above contents are subject to change without further notice! | |