A tabletop reflow oven is a compact device used for soldering surface-mount components onto printed circuit boards (PCBs). It operates by following a precise temperature profile, typically consisting of four stages: preheat, soak, reflow, and cooling. During preheat, the PCB warms gradually to avoid thermal shock. The soak stage stabilizes the temperature, allowing flux to activate. In the reflow phase, the temperature peaks, melting the solder paste to form reliable joints. Finally, controlled cooling solidifies the connections. Modern ovens use infrared heating or convection to ensure even heat distribution, making them essential for small-scale electronics manufacturing and prototyping.

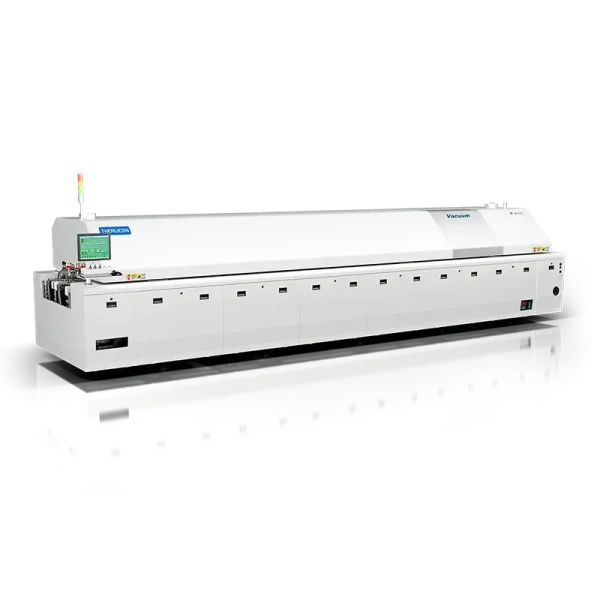

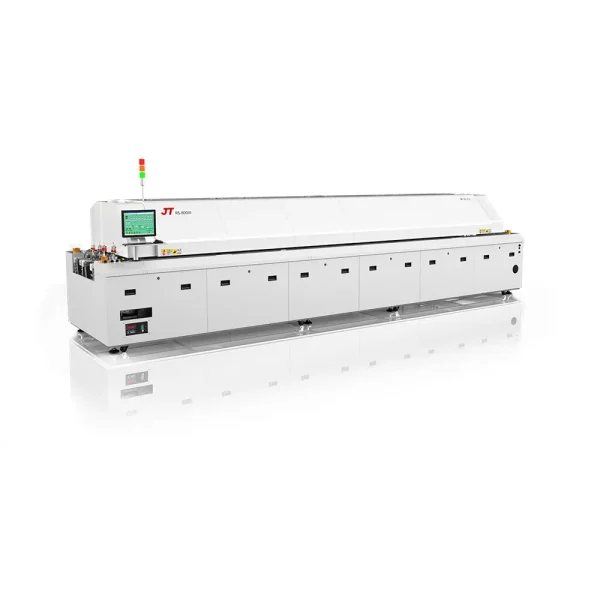

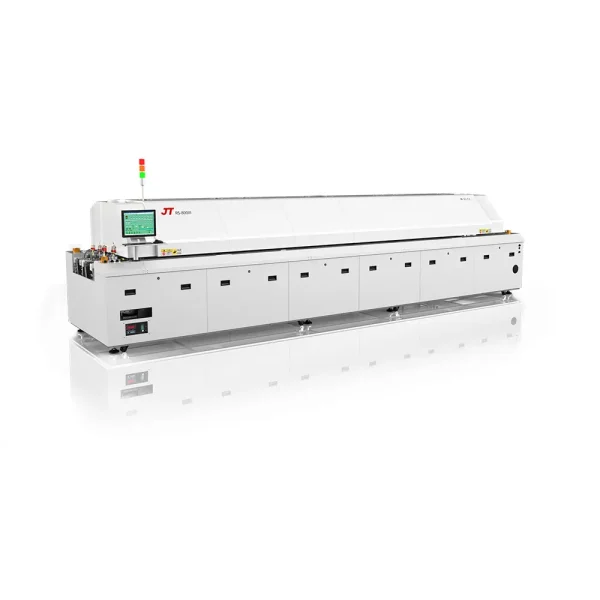

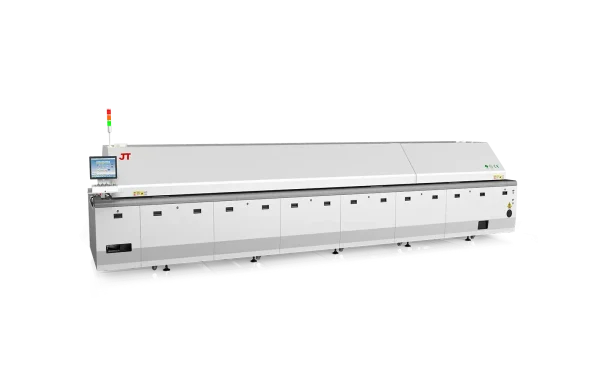

| MODEL | RS-600III/RS-600III-N |

| GENERAL | |

| Outside Dimension(L*W*H) | 4190 x 1430 x 1530mm |

| Weight | Approx. 1850KG/1950KG |

| Number Of Heating Zones | Up 6 / Bottom 6 |

| Length Of Heating Zones | 2295mm |

| Number Of Cooling Zones | Up 1 / Bottom 1 (Cool Air Conversion) |

| Exhaust Volume | 10 m³ / min x 2 (Exhausts) |

| Control System | |

| Electric Supply Required | 3 phase, 380V 50/60Hz (Optional: 3 phase, 400V/480V 50/60Hz ) |

| Electric Power Required | 48KW / 51KW |

| Power For Warm Up | 24KW / 26KW |

| Power Consumption | 6.5KW / 7KW |

| Warming Time | Approx. 20 minute |

| Temp. Setting Range | Room Temp. — 300℃ |

| Temperature Control Method | PID Close Loop Control + SSR Driving |

| Temperature Control Precision | ± 1.0℃ |

| Temperature Deviation on PCB | ± 1.5℃ (by JT Board Test Standard) |

| Commutated Element | Aluminium Alloy Plate |

| Data Storage | Various prameters and status are storable (80GB) |

| Abnormal Alarm | Abnormal Temperature (Extra-high / Extra-low Temp.) |

| Board Dropped Alarm | Tower Light: Yellow–Warming; Green-Normal; Red-Abnormal |

| Conveyor System | |

| Rail Structure | Subsection Integrated Type (Option : Subsection Separate Control) |

| Max.Width Of PCB | 400mm (OPTION :460mm) |

| Range Of Rail Width/Adjustment | 50~400mm / Motorized |

| Components Clearance | PCB Top 30mm/ Bottom 25mm |

| Converyor Direction | L→R (Option: R→L) |

| Fixed Rail Side | Front Rail Fixed (Option:Rear Rail Fixed) |

| PCB Transmission Agent | Air-Reflow =Chain + Mesh , ( N2-Reflow = Chain only and Mesh optional) |

| Converyor Height | 900±20mm |

| Converyor Speed Range | 300~2000mm/min |

| Lubrication Auto-Afflux | Standard |

| Cooling System | |

| Cooling Method | Standard:Forced-Air Type |

Notes: D:Dual rails,Fixed mode is optional,the max width of PCB is 250*250mm;N:Nitrogen;L:the max width of PCB is 610mm

The above contents are subiect to change without further notice.