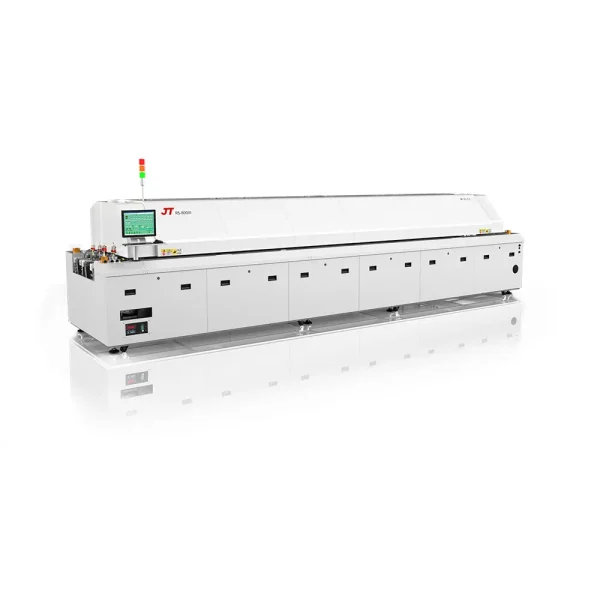

| Model No. | TFO-800 |

| Specification | |

| Heated Length | 3110mm |

| Dimensions (L×W×H) | 5220x1430x1530mm |

| Net Weight | Approx.2250kg |

| Exhaust Volume | 10 m³/min×2 Ducts |

| Supply Power | AC; 380V 3Φ5w 50/60HZ; (Option: 220V 50/60HZ) |

| Power | Starting: 30KW Operating: 9KW |

| Heat up Time | Approx.25min |

| Temp. Range | Room temperature -300°C |

| Max. Width of PCB | 400mm( Option: 450mm ) |

| PCB Top Height | Top 30mm/Bottom 25mm |

| Conveyor Direction | Left to Right( Option:Right to Left ) |

| Fixed Rail Side | Front Rail Fixed ( Option:Rear Rail Fixed) |

| Conveyor Height | 900±20mm |

| Conveyor Speed Range | 300-2000mm/min |

| Data Storage | Various parameters and storable |

| Abnormal Alarm | Abnormal Temp. (Over/under-heat.) Sound & Light Alarm |

| Device Layout | |

| NO.of heating zones | Top 8, Bottom 8 |

| NO.of cooling zones | Top 2 Cooling Zones |

| Control System | WIN10 + Computer + PLC |

| Temp. Control Method | PID+SSR |

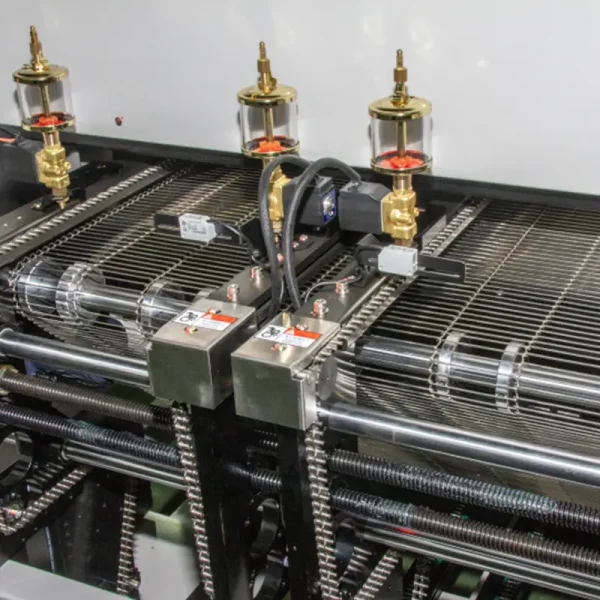

| Thermocouple Wire | 4 wires |

| Conveyor System | Single Rail+ Mesh |

| Conveyor Control Mode | Inverter + Import Conveyor Motor |

| Chain Structure | Single side link avoid block |

| Width Adjustment | Electric adjustable |

| Cover Open | Electric open for easy maintenance. |

| UPS Power | Backup power supply to ensure PCB production finish normally. |

| Cooling System | Forced Air Cooling |

| The above contents are subject to change without further notice! | |

TFO Series Lead-Free Hot Air Reflow Oven

● Rail Conveyor System:

The rail track is dealt with a hardening process to make it more reliable.

● Dual-Rail Conveyor System:

The dual rail system can improve productivity efficiently and save energy and production cost, Strengthen the mail hanging bracket to avoid rail deformation.

● 95% material of reflow oven can be recycled;

● The patented optimized structure design can minimize the influence of the chamber to environmental temperature;

● The automatic flux collection system is easy for maintenance.