EelE Smart Expo was successfully held from July 18th to July 20th. At this exhibition, JT’s exhibited equipment included Solder Paste Detection SPI, Reflow Soldering, and Optical Component Detection AOI, covering the detection and soldering processes on the SMT production line, fully demonstrating JT’s technical strength and strong market adaptability in the SMT industry.

Introduction to exhibited equipment

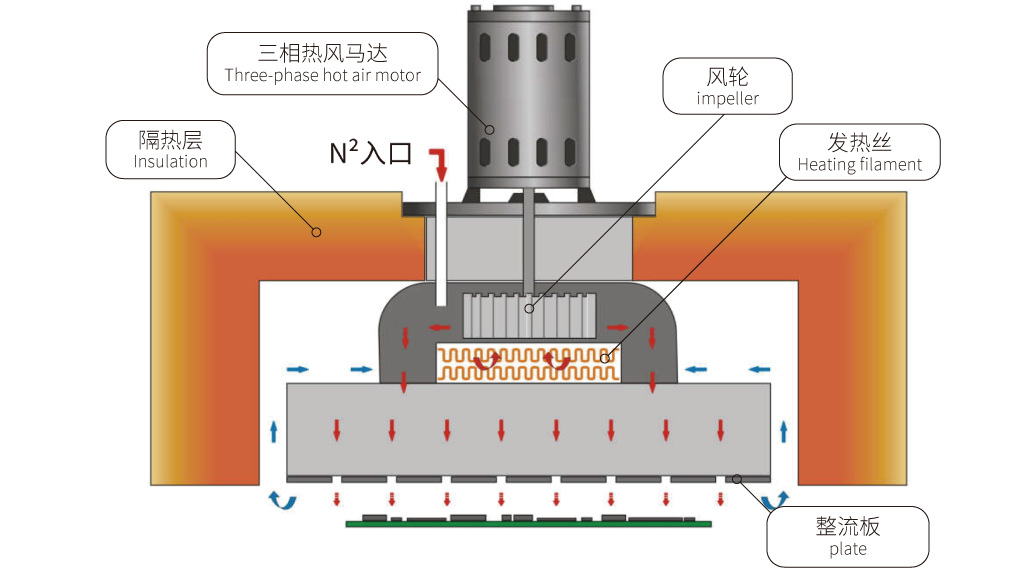

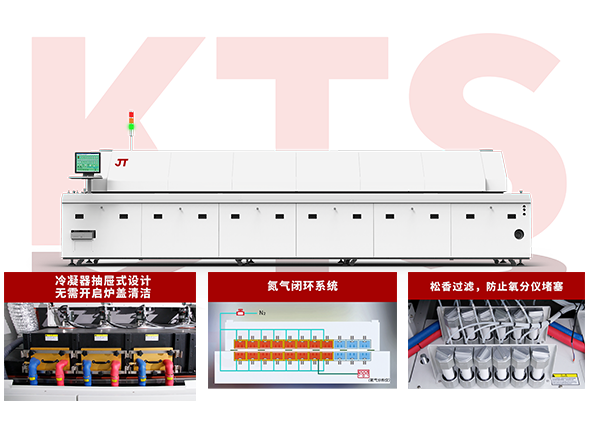

KTS-1204-N

Reflow Soldering is an indispensable part of the SMT production line. JT Reflow Soldering has the characteristics of high production capacity and low energy consumption. The nitrogen is quantitatively controllable throughout the process. The oxygen concentration range is controlled at 50-200PPM, dual variable speed, single machine cost, double production capacity, and energy saving of 65%.

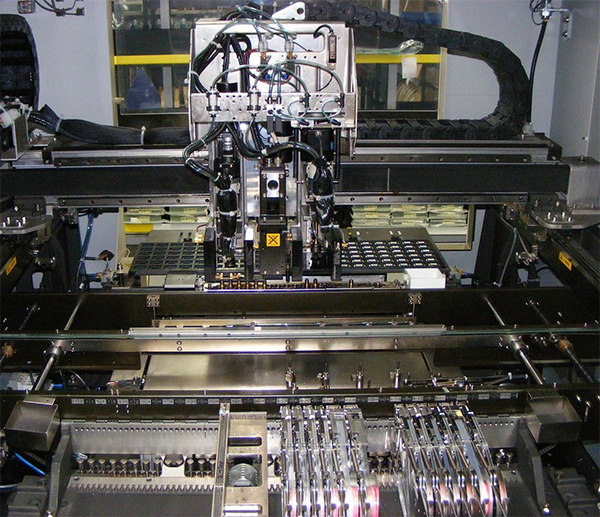

JTA-660TB

Applied post-Wave soldering inspection of PCBA boards, it can detect problems such as missing components, inversion, polarity, etc., soldering problems including excessive tin, cold soldering, and bridging. It can also inspect the solder paste process, epoxy glue process, and the assembly and soldering quality of components on the PCBA after wave soldering.

REFINE-XS

Used for solder paste inspection before patching in the SMT production line, it can detect problems such as excessive tin, insufficient tin, missing paste, paste displacement, foreign matter, and bridge. Based on the 3D solder paste measurement of white light sinusoidal stripe PMP technology, the solder paste height detection accuracy can reach 1um.

Booth grandeur

JT’s exhibited equipment, with its exquisite craftsmanship display, demonstrated its leading strength in the field of industrial automation, attracting the attention of many industry experts and enterprise representatives.

With the successful conclusion of the Smart Expo, JT’s exhibition journey has also come to a perfect end. Looking forward to the future, we will continue to invest in technology research and development, promote the continuous progress and development of the field of industrial automation with more intelligent and efficient products and professional services, and jointly explore the infinite possibilities of intelligent technology to enable industrial transformation.