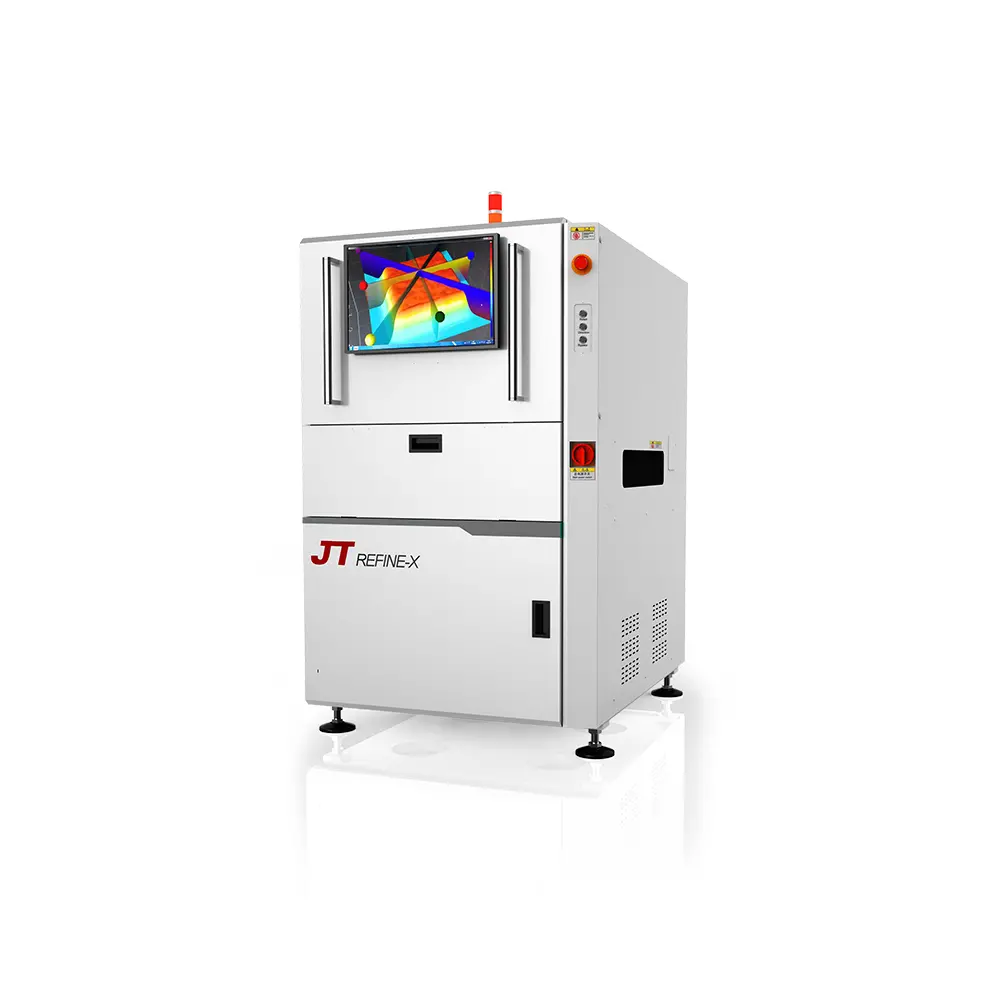

SPI Vision Inspection Equipment

Why use solder paste inspection machine?

After 30 years of rapid development for SMT industry, The component assembly method is from plug-in to SMD, the size of components is getting smaller and smaller, and the pitch of pins is getting denser, which has exceeded the range that can be recognized by human eyes. QFP and other fine pin gap components, PLCC, BGA and other components with solder joints hidden under the body, bring great difficulties to AOI inspection after mounting and AOI inspection after soldering. Many components are inspected after welding, making maintenance difficult and expensive. With the increase of labor costs and the upgrading and transformation of industrial structure, it is an inevitable trend to introduce SPI machine into SMT production lines.

Advantages of JT solder paste inspection machine?

First, inspection capability including inspect defect, inspect accuracy, and inspect speed. JT 3D solder paste inspection based on white-light sine stripe PMP technology ,the inspection accuracy can reach 1um, auto-restore pad 3D date on PCB surface, calculate the volume,area,height and deviation of every solder paste.JT SPI machine use four type of 2D light sources of R, G, B, and W are used to make the image color more realistic, and the software algorithm uses 2D algorithm to make

In addition, improve the recognition rate of bare copper, silk screen, bridging, and foreign objects, improve the detection rate, and reduce misjudgment.

Secondly, programming making function include database collection, database analyse and generate chart. JT SPI machine use graphic interaction interface, comprehensive function and easy to handle. In addition to programming with Gerber file, image-oriented edit mode can also realize off-line programming and debugging.JT solder paste inspection machine have Multi-touch function can realize 3D image rotation and 2D image resizing, convenient to check and confirm solder paste condition.

Thirdly, database statistic, JT SPI machine own comprehensive SPC function includes many kinds of diagrams generation and output; SPC software can record detailed data of volume, area, height and offset of all solder paste on each PCB To calculate CPK, analyze and control the process of the front-end printing machine. JT solder spate inspection machine have imaged accelerate calculations base on multi-GPU, integrated cast iron frame structure, high rigidity can avoid outside vibration interference.

JT made the SPI machine since 2009, we have the powerful R&D and production capability, so if you need solder paste inspection machine, please feel free to contact us.