Achieving optimal performance in PCB assembly starts with selecting the right reflow oven. With various models available, understanding key features and best practices for operation and maintenance is crucial.

This guide highlights essential features, the working principle, energy-efficient options, and maintenance practices for consistent, high-quality results.

Essential Features to Look for When Selecting an SMT

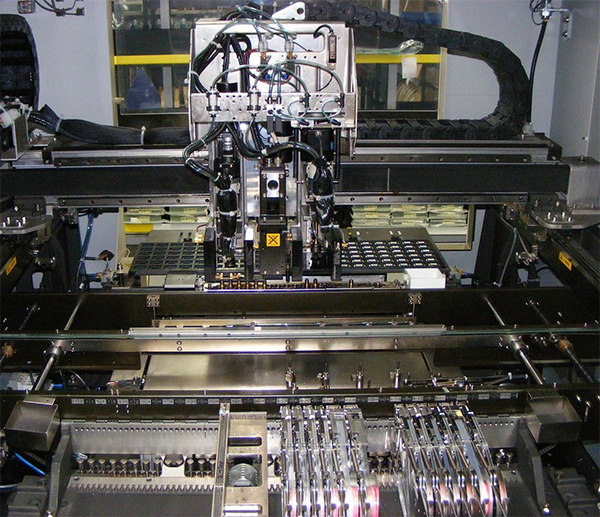

When choosing an SMT, the priority is its temperature control capabilities. Precision in temperature management is vital for consistent soldering quality, preventing common defects like solder bridging or insufficient wetting.

Modern ovens often feature multi-zone temperature controls that enable precise customization of different heating phases.

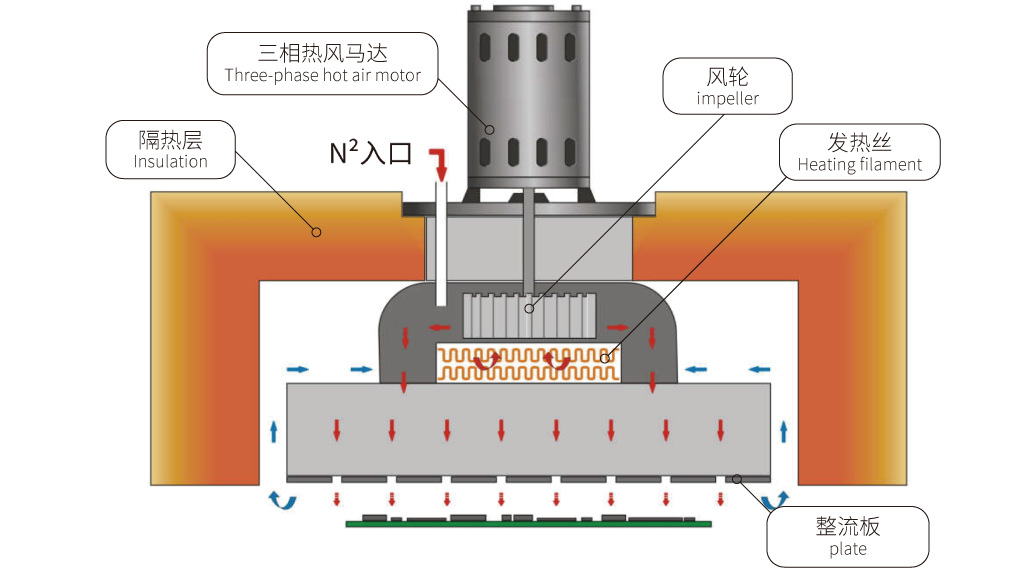

Additionally, uniform heat distribution is key. Advanced airflow systems ensure consistent temperatures throughout the chamber, leading to uniform reflow across PCBs.

SMT Reflow Oven Working Principle

Understanding the SMT working principle can enhance its use and maintenance. The process involves passing PCBs through a series of temperature-controlled phases.

The preheating phase gradually raises the temperature to prevent thermal shock. This is followed by the soaking phase, where the temperature stabilizes to activate the flux and prepare the solder for melting.

The reflow phase is next, where peak temperatures melt the solder and secure connections. Finally, the cooling phase solidifies the solder, ensuring durable joints.

Energy-efficient SMT Reflow Ovens

The energy-efficient SMT Reflow Oven is designed to minimize power consumption while maintaining optimal performance.

These models often feature advanced thermal management systems and improved insulation to reduce energy loss.

Multi-zone temperature control allows for precise heating, minimizing the energy used in each phase of the soldering process.

Additionally, energy-efficient ovens have smart standby modes that lower power usage when not actively processing PCBs.

By selecting an energy-efficient SMT reflow oven, manufacturers can significantly cut operational costs, reduce environmental impact, and maintain consistent, high-quality soldering results, making them a smart investment for modern PCB assembly lines.

Top Maintenance Practices for Optimal Performance

Regular maintenance is essential for keeping a reflow oven running efficiently. Cleaning the oven chamber and inspecting conveyor belts for wear can prevent buildup that could disrupt heat distribution.

Periodic checks and calibration of temperature sensors are also necessary for maintaining accuracy and ensuring high-quality soldering.

Ensuring that cooling zones function well contributes to smoother operation and greater energy efficiency.

The Importance of Cooling Zones for Energy Efficiency

Cooling zones play a crucial role in the efficiency of a reflow oven. A well-designed cooling system ensures that solder joints solidify uniformly, preventing thermal damage and boosting PCB reliability.

Adjustable cooling rates allow customization to meet the requirements of different solder pastes and components. This feature enhances overall performance and supports the energy-efficient operation of the oven.

Conclusion

Choosing the right SMT reflow oven for your PCB assembly involves understanding its working principles, selecting energy-efficient models, and focusing on key features like multi-zone temperature control and robust safety mechanisms.

Implementing top maintenance practices and recognizing the importance of cooling zones will help ensure peak performance and reliable results.

For any PCB assembly line, investing in an SMT that meets these criteria is essential for achieving efficient, high-quality production.