Selective Solder Equipment is an invaluable tool in today’s electronics production, offering numerous advantages like cost-effectiveness, time savings, and quality assurance. Turnkey PCB assembly solutions, which integrate selective solder equipment, enable companies to focus on innovation and streamline their PCB production processes.

What is Selective Solder Equipment?

The solder is placed selectively on some areas of a printed circuit board (PCB), usually around through-hole components, so as not to impact adjacent components or areas. This method works exceptionally well for PCBs that contain both through-hole and surface-mount components.

Comparison with Other Soldering Methods

1-Wave Soldering:

It involves passing the whole PCB through a wave of molten solder. It can be efficient but needs more precision of selective soldering, especially for boards with mixed technology.

2-Manual Soldering:

It involves a technician soldering components by hand. It offers flexibility but can be time-consuming and less consistent than automated selective soldering.

What is the Working Principle of Selective Solder Equipment?

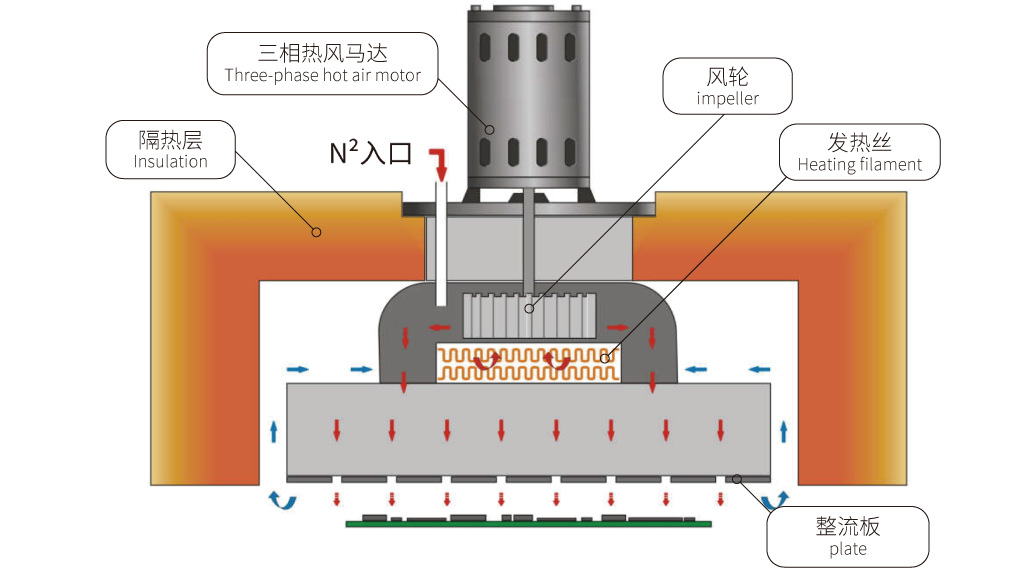

Selective solder equipment is designed to apply solder to specific areas of the PCB using a precise, controlled process. This equipment consists of several critical components that work together:

1. Flux Sprayer: This tool applies flux to the PCB to ensure the solder adheres appropriately to the components. The flux also helps prevent oxidation during the process.

2. Preheater: This device warms the PCB to the appropriate temperature. It also allows the solder to bond correctly and reduces thermal shock to the components.

3. Solder Pot: Holds molten solder at a controlled temperature, ready for application to the PCB.

4. Solder Fountain: A precisely controlled nozzle directs molten solder to the areas requiring soldering, ensuring minimal impact on the rest of the board.

Benefits of Integrating Automated Solutions with Selective Solder Equipment

1. Improved Accuracy: Its automated systems ensure that solder is applied consistently and precisely.

2. Increased Throughput: Automated machines can process multiple boards quickly, reducing production times.

3. Reduced Human Error: Automated systems minimize inconsistencies and defects caused by manual soldering.

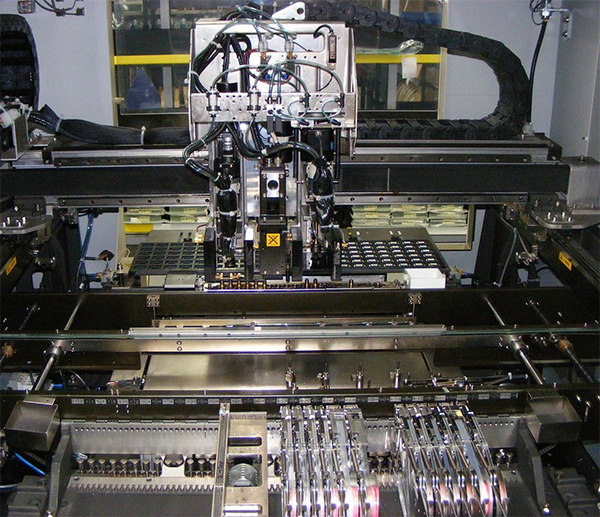

Examples of Automated Systems Used in Selective Soldering

- Robotic Arms

- Vision Systems

Advantages of Selective Solder Equipment

- Precision and Accuracy: Selective soldering offers exceptional control over where solder is applied, making it ideal for complex PCBs with densely packed components.

- Reduced Waste: Since only the necessary areas are soldered, solder and flux are wasted minimally, leading to cost efficiency.

- Handling Complex PCB Designs: Selective solder equipment can easily manage boards with mixed component types, such as through-hole and surface-mount components.

Maintenance of Selective Solder Equipment

Regular maintenance is vital to ensure that selective solder equipment functions optimally. Neglecting maintenance can result in poor solder joints, equipment failure, and reduced lifespan.

Common Maintenance Tasks

1. Cleaning the Solder Pot and Nozzles: Residual solder can build up, leading to clogs and inconsistent soldering. Regular cleaning is essential.

2. Checking and Replacing Worn Components: Over time, parts such as nozzles, flux sprayers, and heating elements may wear out and need to be replaced.

3. Calibration Procedures: Proper calibration of temperature controls, solder flow rates, and nozzle movements is crucial for maintaining accuracy.

Conclusion

Selective solder equipment is an essential tool in modern PCB assembly, offering precision, efficiency, and the ability to handle complex designs. As the electronics industry evolves, manufacturers are encouraged to adopt advanced selective solder solutions to improve quality, reduce costs, and streamline production.