In today’s fast-paced business environment, organizations need to leverage the power of technology to stay competitive. Automation solutions transform industries by streamlining processes, reducing human error, and enhancing productivity. Whether in manufacturing, logistics, or other business sectors, integrating automation systems can significantly improve operational efficiency and cost savings.

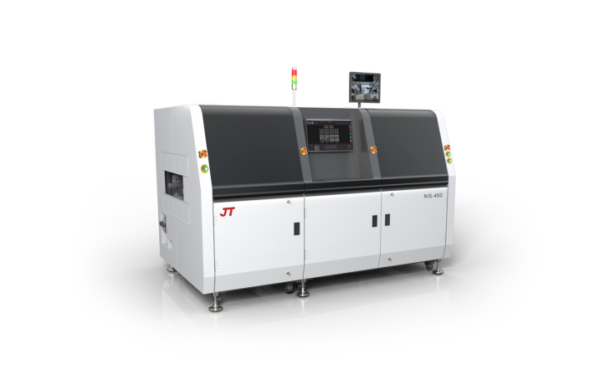

At JT International, we specialize in providing cutting-edge automation solutions designed to meet the unique needs of industries in high-tech electronics manufacturing. Our focus on delivering customizable, top-tier equipment and technology allows companies to scale operations and optimize workflows effortlessly.

Benefits of Using Cutting-Edge Solutions

One of the most compelling reasons companies invest in automation solutions is the immediate production quality and speed improvement. Automation solutions replace time-consuming manual tasks with reliable and fast systems that can work around the clock. This leads to fewer errors, lower labor costs, and the ability to meet tight production schedules without sacrificing quality.

Additionally, automation fosters workplace safety by reducing the need for human involvement in potentially hazardous or repetitive tasks. Automated systems are equipped to handle complex procedures that would be risky or inefficient for human workers, which not only protects employees but also improves overall process reliability.

How JT International Stands Out

When it comes to industrial automation, not all solutions are created equal. JT International offers more than just products; we deliver complete automation systems tailored to your business’s exact needs. From conceptual design to full-scale integration, we provide:

- Robust hardware solutions: Our systems include a Transmission system, and a collection system, ensuring seamless operation in even the most demanding environments.

- Customizable software: We design software that integrates with your existing systems, enabling full automation and control over production lines.

- Technical support: Our team is available for ongoing support, maintenance, and updates, ensuring that your automation systems perform at their peak long after implementation.

Featured Products

At JT International, we offer a range of high-quality automation solutions to enhance your production capabilities:

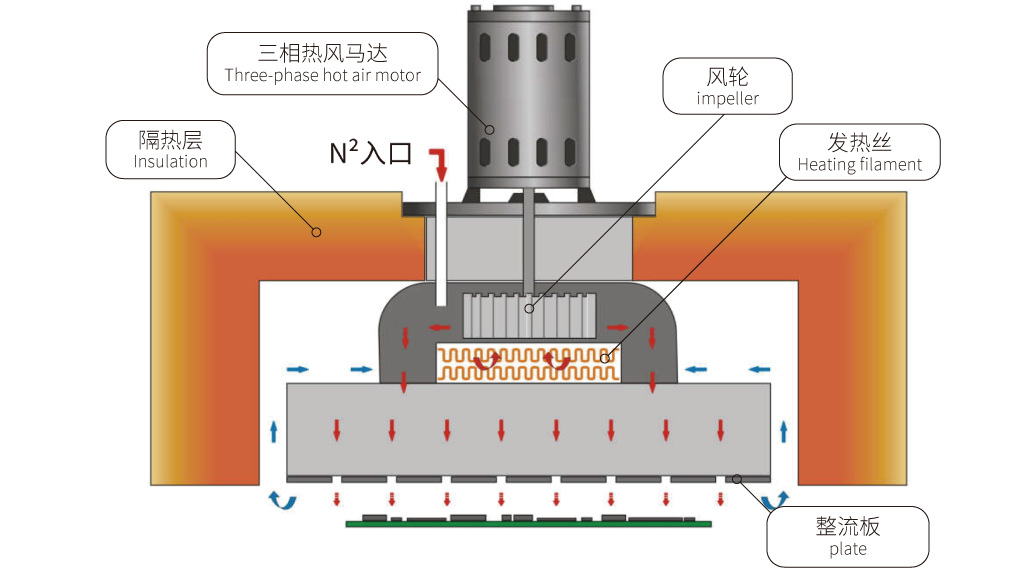

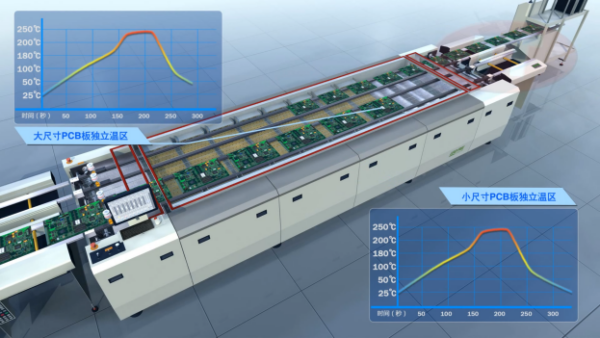

- CFO Series Lead-Free Hot Air Reflow Oven: This state-of-the-art reflow oven is designed for lead-free soldering, ensuring precise thermal management across the entire production line. Its advanced control system allows for consistent heating, making it ideal for producing high-reliability electronic assemblies.

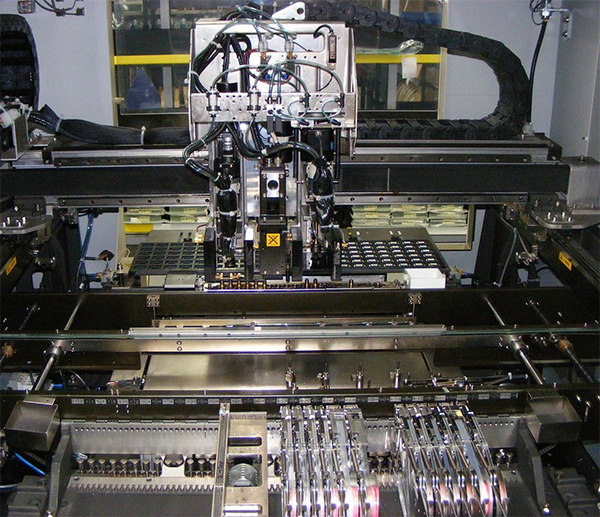

- JNS Integrated Selective Wave Soldering: Selective Wave Soldering combines efficiency with precision, offering selective wave soldering capabilities that ensure flawless solder joints in high-density electronic components. The maximum size of PCB is 710*610mm, and the modularized equipment combination is adopted to meet the customer’s high capacity requirements.

- Solder Joint and Component Inspection AOI JTA-660B: The JTA-660B is an advanced Automatic Optical Inspection (AOI) system designed for inspecting solder joints and components. It uses high-resolution cameras and intelligent software to detect defects early in the production process, ensuring high product quality and reducing rework costs.

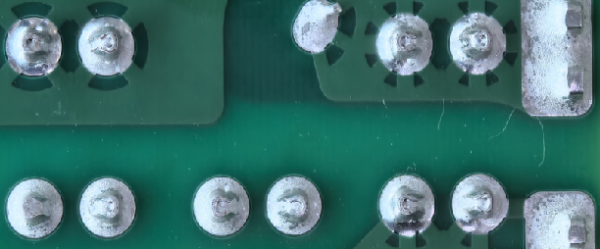

- 3D Solder Paste Inspection SPI: This 3D SPI system delivers precise inspection of solder paste deposition, which is crucial for ensuring consistent and high-quality solder joints. Its advanced 3D imaging capabilities allow manufacturers to identify potential defects before the assembly process begins, boosting overall yield rates.

Streamlining Your Industry with JT International

Whether you operate in the Automotive, Aerospace, or Medical equipment industry, our solutions are designed to meet your specific needs. Automation ensures compliance with stringent quality control regulations by maintaining precise standards throughout the production process, At the same time, it also improves efficiency and achieves precise and efficient production needs.