Vertical curing oven is a significant type of industrial equipment used to provide controlled heating and drying processes on a variety of materials. The vertical design of the ovens guarantees efficient space use while distributing the heat uniformly through the curing process. From automobile and aerospace industries to electronics and textiles, vertical curing ovens play a great role in obtaining better quality and performance in the products.

Basic Knowledge of Vertical Curing Ovens

This kind of vertical curing oven provides heat treatment on materials by curing them in vertical positions. Usually, it leads to industries with a sense of height or efficiency. Because the vertical orientations will occur, the products that have a tall height like automotive parts or fiberglass parts and electronics are going to be processed appropriately without any restraint caused by horizontal designs.

Vertical curing ovens are equipped with advanced heating mechanisms, precise temperature controls, and better insulation. Such ovens are designed for a wide range of materials, either metals or plastics or composites and ceramics.

Applications of Vertical Curing Ovens

Coating and Painting Application

Vertical curing oven is used by any industry that needs to cure coatings or paints. For example, its applications include coatings applied to parts such as automotive panels or rims and cured for optimum strength and finish.

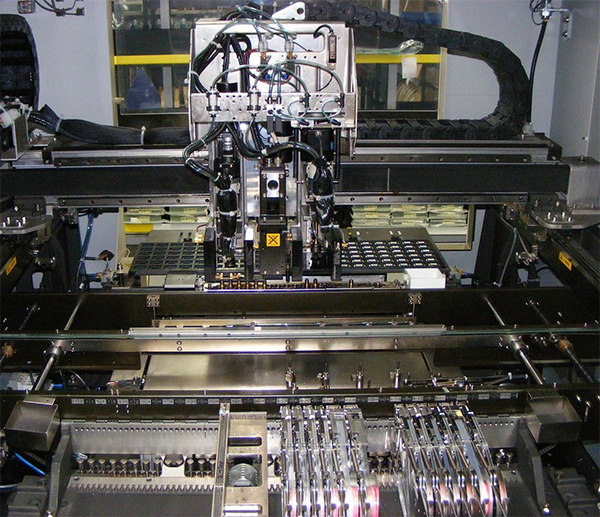

Electronics Manufacturing

In the electronics industry, curing ovens in a vertical mode are used for curing adhesives, sealants, or encapsulants applied in assembling electronic components.

Aerospace Components

Extremely high in the importance scale in terms of aerospace where composites have to be curable to absolute perfection.

Curing of textiles and fabrics.

Processing Materials like vinyl and other lamination are often put into practice for the fabric/textile by utilizing vertical curing ovens.

Curing Process for Vertical Curing in Ovens

Curing for achieving properties by putting it under a step process which comprises curing properties generally; such has a basic following: Pre-preparatory work.

Preparation

Pre-processing of the material is done as needed by the curing process. Coating, bonding with adhesives, and other processes can be done on the materials before they go into the oven.

Heating

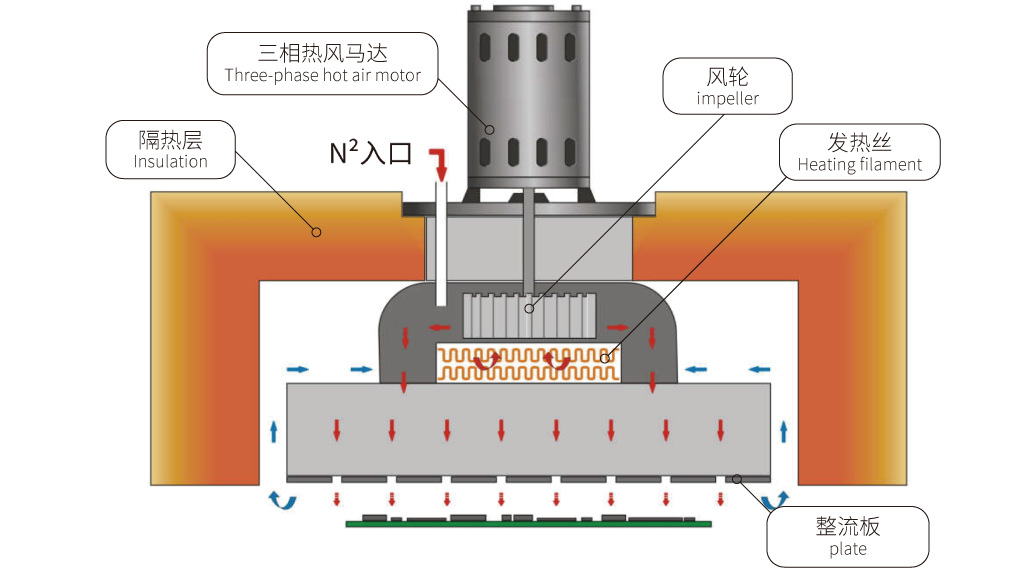

The vertical curing oven utilizes controlled heating elements to heat the materials. Precise temperature control is maintained at all times during the process to avoid overheating and ensure uniform curing.

Ventilation and Airflow

This comprises proper flow of air to ensure heat in the oven would be equally divided to all places. Proper venting avoids the buildup of hot spots, thereby allowing uniform curing.

Cooling takes place gradually in an oven in a controlled rate after the curing of the material has taken place. This helps prevent thermal shock on cooling and strives to make uniform all properties in the cured material.

Quality Control

After processing, the cured product is inspected and reviewed for proper quality to ensure it passes through the industry standards and specifications.

Conclusion

A vertical curing oven could be termed as a prominent part of modern industrial practice. They are efficient, reliable, and accurate in their cure of any product material. This appliance is very flexible with its application for various industries and products; therefore, it is a vital tool that improves product performance and longevity.