An AOI system improves the efficiency of your production line by reducing manual inspection time from hours or days to just minutes per unit. There are many factors to consider when choosing the right AOI machine for your needs. In this blog post, we will discuss these factors as well as some helpful tips on how to choose the best AOI solution for your specific needs and budget.

What is an AOI Machine?

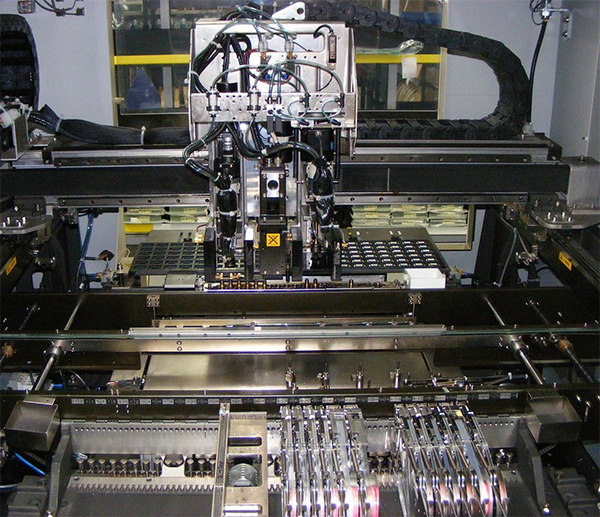

An automated optical inspection machine is used for quality control and inspection of products. It is an imaging device that uses a camera with a special lens to take pictures of a product, process, or production line. AOI machine uses a computer program to analyze this captured data to find any flaws or imperfections on the product or production line.

There are many different types of AOI systems that can be used in a wide range of industries, including semiconductor, medical, automotive, consumer goods, aerospace, and many more. These imaging devices can inspect products that are difficult to see by manual .

AOI cameras can inspect PCB boards used in these industries or flaws, defects, and also identify different parts or products to ensure that everything is correct, accurate, and meets your standards. AOIs can also be used to inspect product properties like color, shape, and size to ensure consistency and quality. These optical devices can perform many functions that are not possible or are difficult by hand. They can capture images and data instantly, detect defects that the human eye would miss, and process tons of data in seconds to give you valuable information.

Why You Should Use an AOI Machine?

If you are a manufacturer in the SMT or DIP industry, you will need to use the AOI equipment to inspect the PCB board yield to ensure that the product meets your quality standards.

AOI systems can drastically reduce the time it takes to inspect products with thousands of times more accuracy than the human eye. AOI systems can inspect products quickly and accurately, and they can help you meet product demand and deliver your customers the high-quality products they expect.

Things to Consider Before Purchasing an AOII Machine

There are many different factors to consider before purchasing an AOI machine. Here are some important factors to keep in mind when shopping for your new AOI system. – Application – The first step when choosing the right AOI for your needs is determining what application you are using it for.

An AOI designed for one application may not be appropriate for another application and vice versa. – Budget – A key factor when purchasing any new equipment or tool is your budget. An AOI system can be an expensive purchase, but it can help you save time and money in the long run by inspecting products more quickly and accurately.

1. Size

The size of your machine is important because it will determine the size of the items you can inspect with it. Be sure to choose a machine that can accommodate the largest item you need to be inspected. –

2. Speed

The speed of your system will depend on how it is set up and used. The faster your system inspects the product, the less time it takes for the entire production process. A slower system might take hours to inspect a piece of product, while a faster system can do the same thing in just minutes.

Other Things to Know Before You Buy an AOI System

If you have never used an AOI before, be sure to keep these things in mind before purchasing your new machine. –

1. Accuracy

The accuracy of your AOI system will determine how many errors (if any) it will find. A system with low accuracy will find mostly false positives or mistakes. A high-accuracy system will find only true positives and no false positives. –

2. Cost

The cost of your AOI machine will depend on the type of system you purchase, the size of the system, and the brand of the system. – Maintenance – Be sure to perform regular maintenance on your AOI machine to keep it running smoothly and efficiently. –

3. Security

Many AOI systems come with built-in security features to prevent tampering or malicious attacks. –

4. Support

Before purchasing your new AOI system, make sure to read any available reviews and contact the manufacturer if you have any questions.

What is the Best AOI Inspection, AOI Equipment Manufacturers in China?

The importance of AOI equipment and inspection for manufacturing and quality control businesses cannot be overstated. If you’re looking for top-notch AOII visual inspection equipment, or AOI machine JT is your best option. We have the most up-to-date equipment on the market. We deal in all kinds of AOI machines that are listed below.

- Solder Joint and Component Inspection AOI JUTI

- Solder Joint and Component Inspection AOI JTA 518D

- Solder Joint and Component Inspection AOI JTA D100

- Solder Joint and Component Inspection AOI AOI1200

- Solder Joint and Component Inspection AOI JTA-660B

If you need a consultant before purchasing the right machine you can call us at +86 18128814211 or email us oversea-sales@jt-ele.com. For more information visit our website, https://www.jt-int.com/.

Conclusion

An AOI machine is an important tool used for quality control and inspection of products. While the process of manually inspecting a product can take hours, an AOI system can inspect a product in just minutes.

An AOI system uses a camera with a special lens to take pictures of a product, process, or production line. The computer program analyzes this captured data to find any flaws or imperfections on the product or production line.

When choosing the best AOI solution for your production needs, you must first determine what type of system works best for your needs. There are many important factors to consider when purchasing an AOI machine. An AOI machine is an important tool used for quality control and inspection of products.