NEPCON THAILAND ended perfectly, JT’s new generation of fully automatic repair solutions attracted strong attention, looking forward to seeing you again!

The highly anticipated NEPCON THAILAND 2024 ended successfully today. JT demonstrated industry-leading technology and innovation at this exhibition. At the same time, it also had the opportunity to have in-depth exchanges with industry elites worldwide to jointly discuss the future development direction of the electronics manufacturing industry.

01 One-stop zero-defect production solution

The exhibited equipment this time is pre-furnace AOI inspection, selective wave soldering rework, and post-furnace AOI inspection in order. The new generation of advanced technology has a repair yield of 99.95%; it has greatly helped the upgrading of product quality in the fields of new energy vehicles, medical devices, communication electronics, aerospace, and other electronic manufacturing industries.

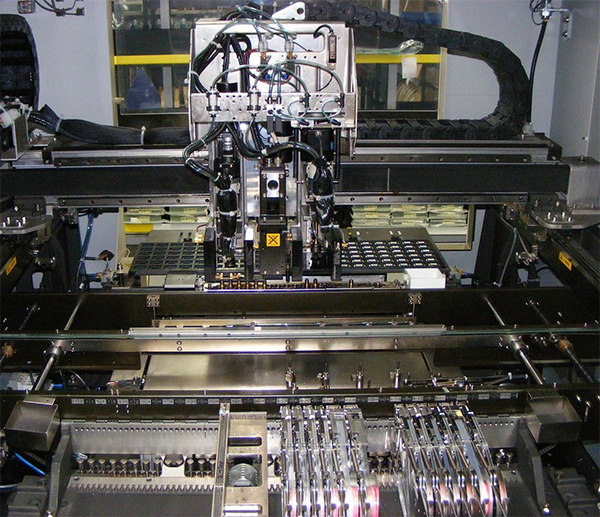

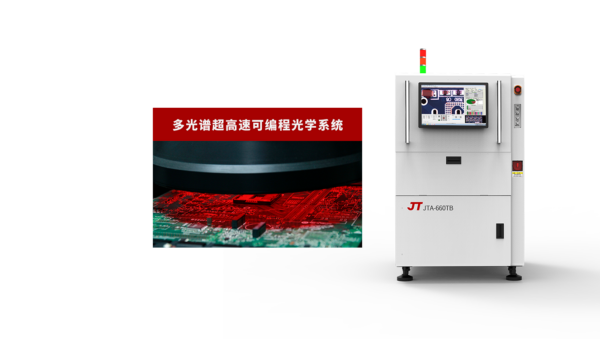

The pre-furnace component inspection AOI uses feature recognition and image contrast for inspection. It is commonly used for appearance inspection before plug-in and soldering. It can detect component missing parts, polarity, wrong parts, multiple insertions, foreign objects, etc. The inspection before soldering greatly reduces the difficulty and cost of rework.

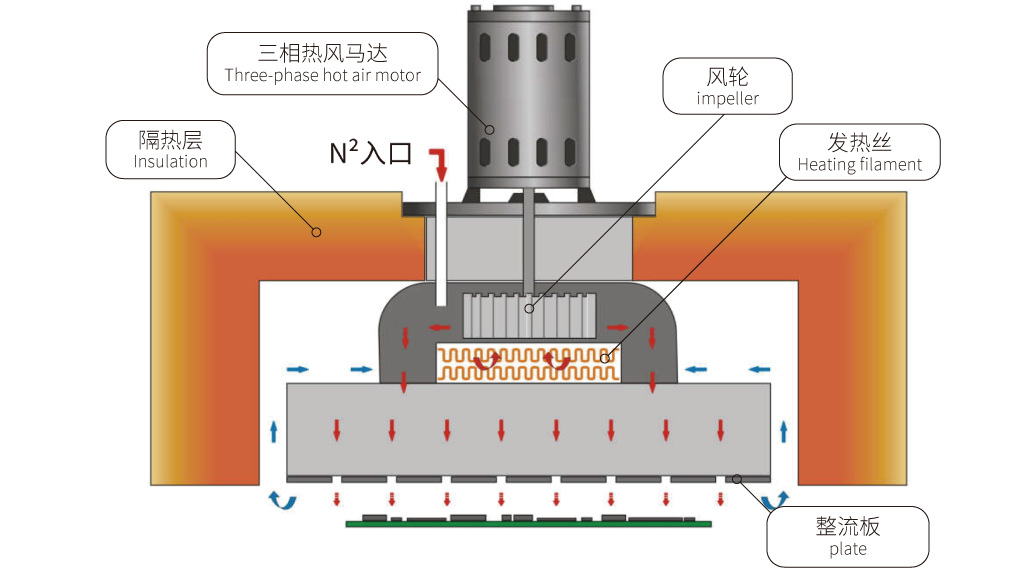

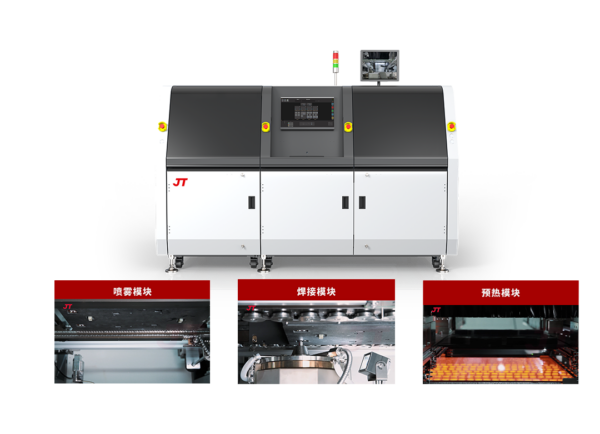

Selective wave soldering can achieve accurate repair of bad soldering points through parameter setting. The modular equipment combination can maximize the customer’s production capacity needs. Its welding accuracy is as high as ±0.15mm, ensuring the high quality and reliability of the repair work. With these advantages, JT selective wave soldering can complete high-quality repair tasks and provide production support for customers.

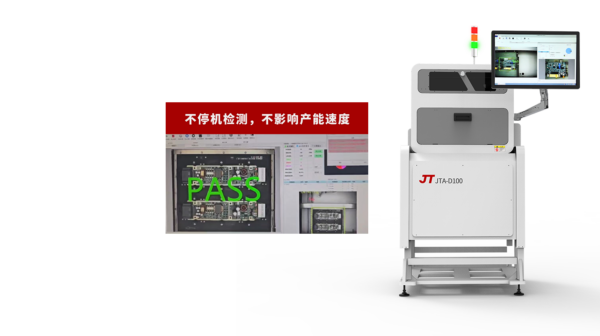

AOI is used for the inspection of repaired PCBs after selective wave soldering. In the repair stage, unqualified ones will be sent to selective soldering for re-inspection by the defective product separator. It provides a guarantee for the product yield, improves the front-end process, and achieves the goal of zero defects in the production line.

02 New opportunities for industry exchanges and cooperation

During the exhibition, JT’s influence and appeal in the industry attracted many professional visitors to stop and built a broader cooperation bridge for us with the industry and beyond.