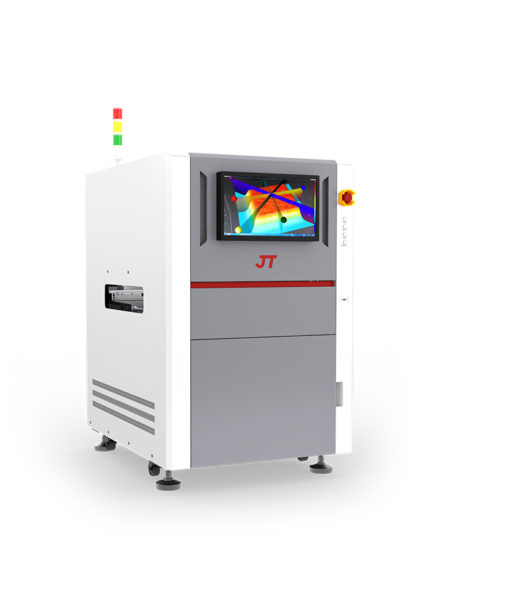

SPI is used to detect the quality of solder paste printing in SMT production lines. It can detect components promptly before reflow soldering as a means of quality process control. JT SPI hardware and software configurations have been newly upgraded, with a detection speed of up to 0.35-0.55S/FOV. At the same time, it can also be used for silver paste printing detection in semiconductor packaging, with higher flexibility and adaptability.

I. Using DLP digital grating projector-high-precision imaging and diversified algorithms

The traditional mechanical grating projector has limited accuracy and insufficient flexibility in detection. In practical applications, SPI using a DLP light structure projector has high-speed, high-resolution, and high-contrast detection capabilities.

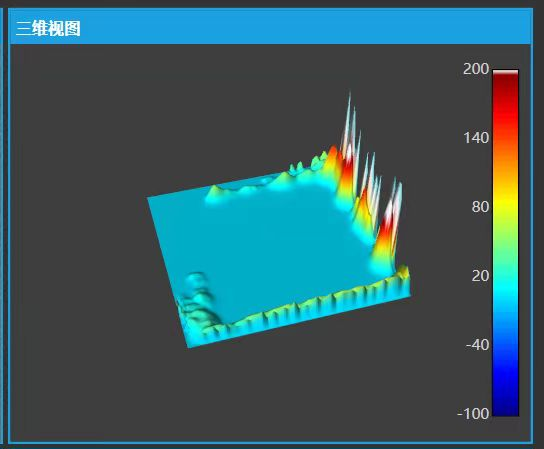

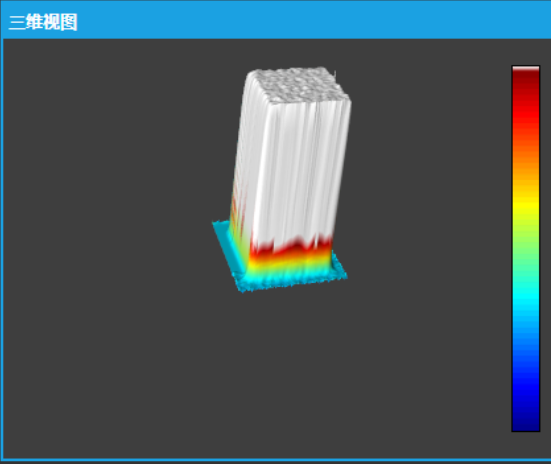

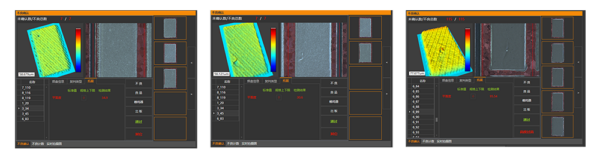

1. Optimization of the measurement span

When the solder paste height is greater than the range, the imaging will not match the actual height.

After the upgrade

The range is upgraded from 0-600um to 0-1100um. The measurement height range is large and the imaging restoration is high

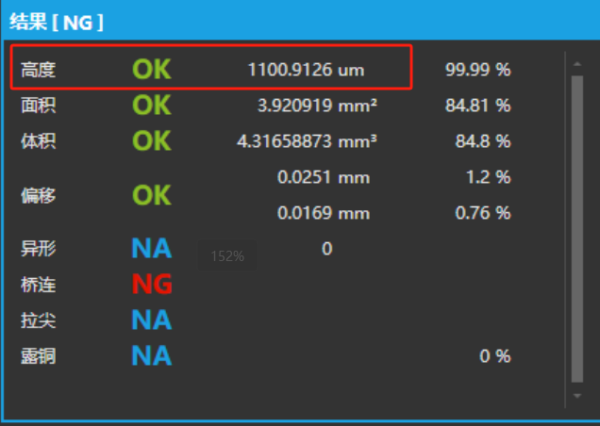

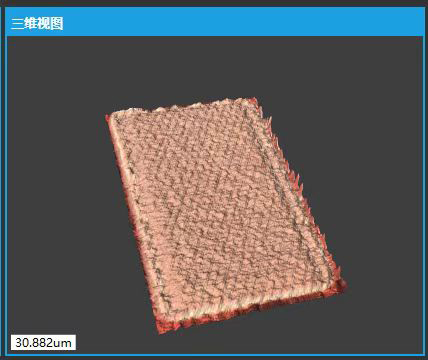

2. More aesthetically pleasing imaging

After the imaging is beautified, the 3D point cloud has no obvious sawtooth and the sinusoidal property is better

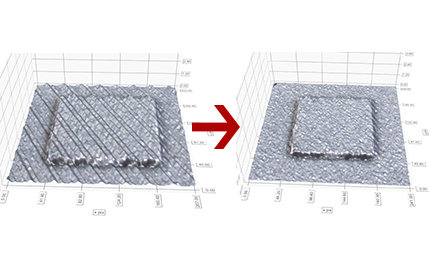

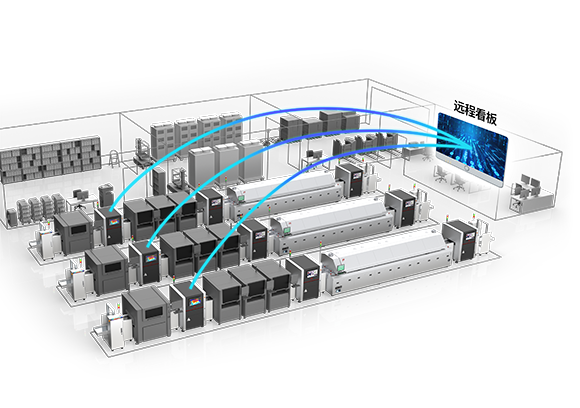

II. Remote re-judgment of multiple machines by one person – saving labor costs

Solder paste detection will be checked through the Statistics Process Control (SPC) tool to predict the process trend of solder paste printing. It rewrote the SPC software to achieve one person controlling multiple machines, which saves labor costs, makes the production process smoother, and improves overall production efficiency.

Before the upgrade

Each device on the production line is equipped with a separate computer, and a corresponding number of operators are required to monitor, record, and handle exceptions in real-time.

After the upgrade

The “one-to-one” monitoring method has been changed, and only one person is needed to centrally monitor and manage the data.

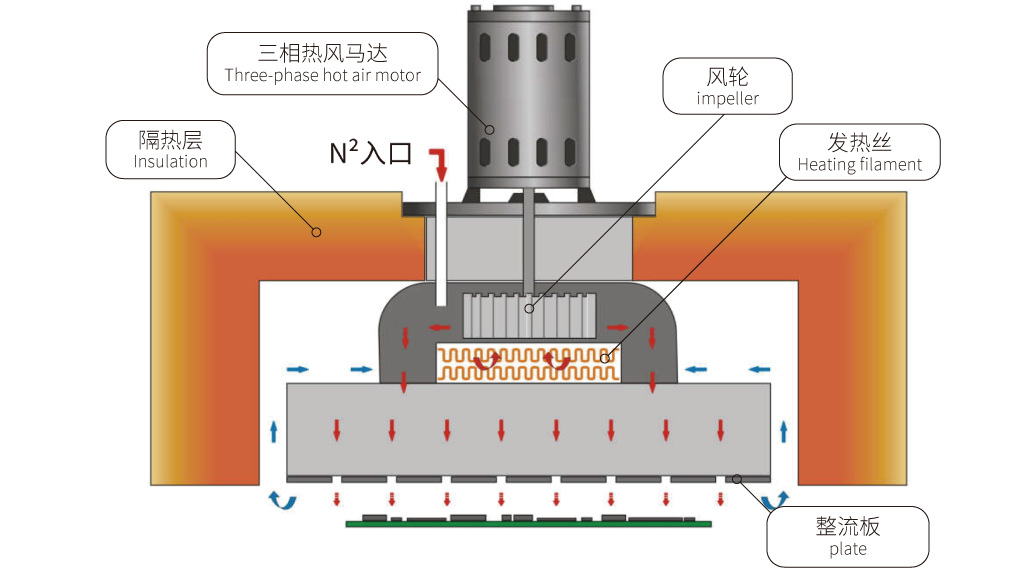

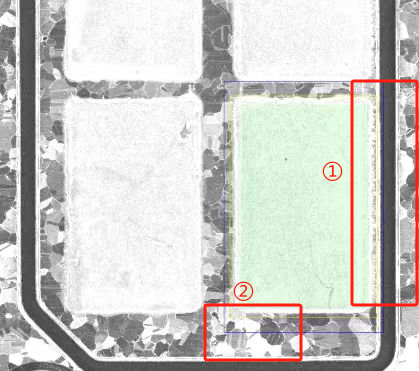

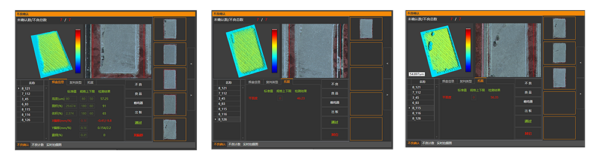

III. Optimizing the zero plane calculation method – adapting to complex application scenarios

The calculation method of the zero plane is crucial to ensure the accuracy of the detection. Traditional SPI systems may face zero plane misjudgment problems caused by complex scenarios such as impurities around the solder paste, background color, reflectivity, geometric morphology, etc., which in turn affects the accuracy of solder paste detection.

Target detection board

Complex detection scenarios: ① There are grooves around the periphery ② The background reflection difference is large

Detection results

It is still possible to accurately and stably calculate the zero plane, Imaging reflects the height of the target.

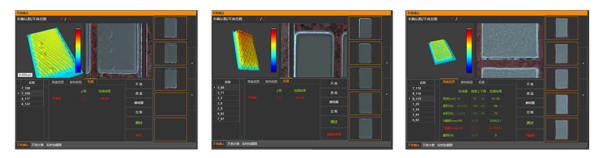

IV. Customer Case: Detection Imaging Display-Silver Paste Printing Detection

The application of SPI technology to silver paste printing detection is also a highlight of this innovative application. Silver paste is a key material for connecting substrates and chips. The upgraded SPI height detection accuracy (correction module): 1um, repeatability (volume/area/height): <1μm@3sigma, providing more reliable quality assurance for semiconductor packaging processes.

Imaging of test results

SPI is a quality inspection tool in the SMT lines, and its performance upgrade is an important driving force for improving welding results. JT, as an excellent enterprise model committed to improving product quality, insisting on independent research and development, and independent innovation, will also promote the innovation and development of industrial visual inspection technology with a forward-looking vision and unremitting efforts in the future.