Wave soldering has long been a critical process in the manufacturing of electronic devices, offering a reliable and efficient way to solder components to printed circuit boards (PCBs). As technologies evolve, the method has seen enhancements in defect prevention, lead-free soldering, and automation. This article will explore the advantages of wave soldering, including its strengths in quality control, its role in environmentally friendly production, and how it compares to reflow soldering.

Defect Prevention and Quality Control

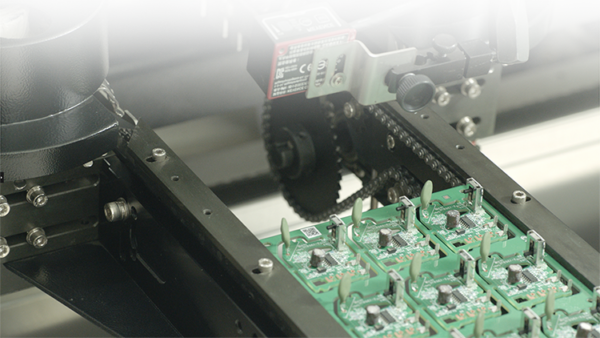

One of the standout advantages of wave soldering is its ability to significantly reduce defects during the manufacturing process. The method involves passing the PCB over a molten wave of solder, which ensures a consistent and uniform application. This reduces the risk of cold joints, bridging, and insufficient solder, common problems that can affect the quality and reliability of the finished product.

Modern wave soldering machines are equipped with advanced quality control systems. These systems can detect potential issues early in the process, such as misalignments or temperature fluctuations, which can be immediately corrected. As a result, manufacturers can achieve higher yields and better product quality with fewer instances of rework or scrap, leading to cost savings and improved efficiency.

Lead-Free Soldering

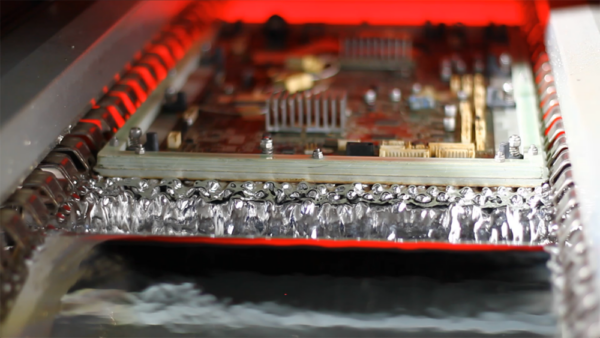

With growing environmental concerns and regulations, lead-free soldering has become a critical aspect of modern electronic manufacturing. Traditional wave soldering uses lead-based solders, but today, lead-free alloys are the industry standard. While lead-free soldering presents some challenges, such as higher melting points and potential joint brittleness, wave soldering machines have adapted well to these new requirements.

The ability of wave soldering to handle lead-free alloys with minimal adjustments ensures that manufacturers can comply with regulations like the Restriction of Hazardous Substances (RoHS) directive without sacrificing quality or efficiency. The process also ensures that components are safely soldered, maintaining the same level of reliability as traditional lead-based solders.

Comparison Between Wave Soldering and Reflow Soldering

When comparing wave soldering to reflow soldering, it is essential to understand the differences in application and results. Wave soldering is typically used for through-hole components, where the leads pass through the PCB, while reflow soldering is more commonly used for surface-mount components.

Wave soldering excels in handling larger volumes of boards with through-hole components. It is more suited for boards with mixed technologies, offering better defect prevention for through-hole solder joints. Reflow soldering, on the other hand, is more flexible for surface-mount technology (SMT) and is often used in the assembly of more complex, densely packed boards.

While reflow soldering offers precision for SMT, wave soldering is the preferred choice for high-throughput, large-scale production environments where speed and uniformity are critical.

Automation of Wave Soldering

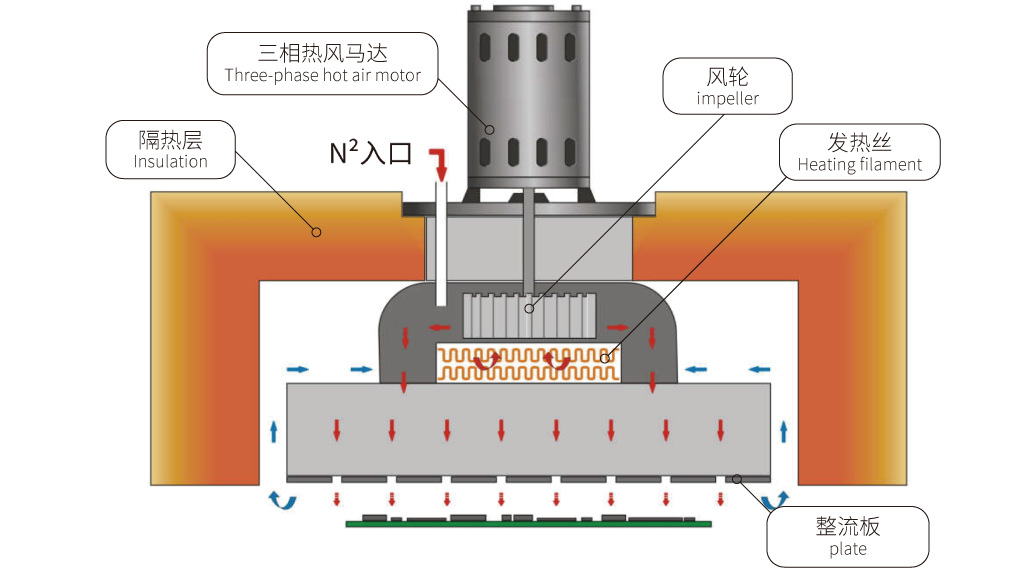

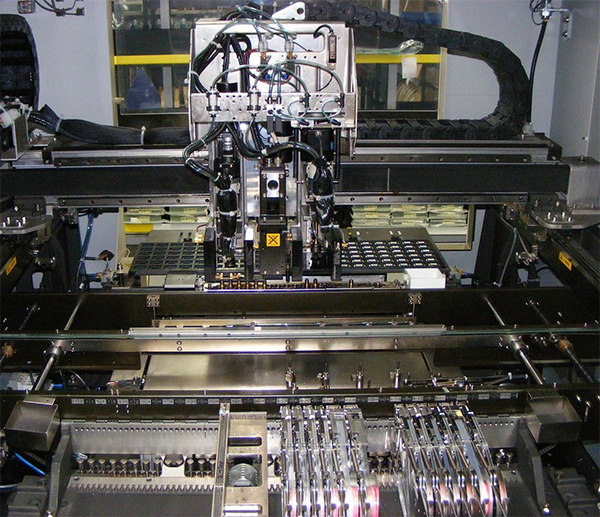

Automation has brought significant advancements to wave soldering, further enhancing its efficiency and precision. Automated wave soldering systems allow for better control over parameters such as temperature, solder flow, and conveyor speed. This results in improved consistency and fewer defects, even in large-scale production.

In addition to quality control, automation minimizes the need for human intervention, reducing labor costs and human error. These automated systems can also be integrated with other manufacturing processes, creating a seamless and efficient production line. The flexibility of automated wave soldering makes it an ideal solution for both small and large production runs, allowing manufacturers to scale their operations as needed.

Conclusion

Wave soldering remains a vital part of electronic manufacturing, particularly for through-hole components and mixed technology boards. Its ability to prevent defects, ensure quality control, and adapt to lead-free soldering standards makes it a highly efficient method. When compared to reflow soldering, wave soldering offers clear advantages in high-volume production, especially when automation is factored in. For manufacturers looking to optimize their soldering processes, wave soldering continues to be a reliable and advanced solution.

For more information on advanced wave soldering systems, visit JT, a leader in PCB manufacturing technologies.