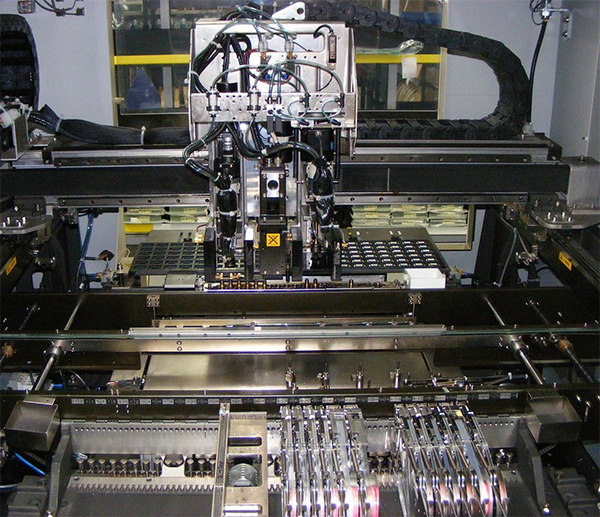

In the constantly changing landscape of electronics manufacturing, accuracy and efficiency are of utmost importance. One key process that ensures seamless assembly of printed circuit boards (PCBs) is hot air reflow soldering. This process carried out in a specialized device called a hot air reflow oven, guarantees reliable connections between electronic components and the PCB.

From smartphones and laptops to medical devices and automotive systems, these ovens play a crucial role in creating the electronic devices we rely on daily. But what exactly is a hot air reflow oven, how does it work, and why is it so important? Let’s find out!

What is a Hot Air Reflow Oven?

A hot air reflow oven is a specialized device used in electronics manufacturing to solder components onto PCBs. This process involves heating solder paste to a temperature where it melts, forming strong electrical connections between components and the PCB. Hot air reflow ovens are essential in producing high-quality, durable electronics, ensuring precision and efficiency during the soldering process.

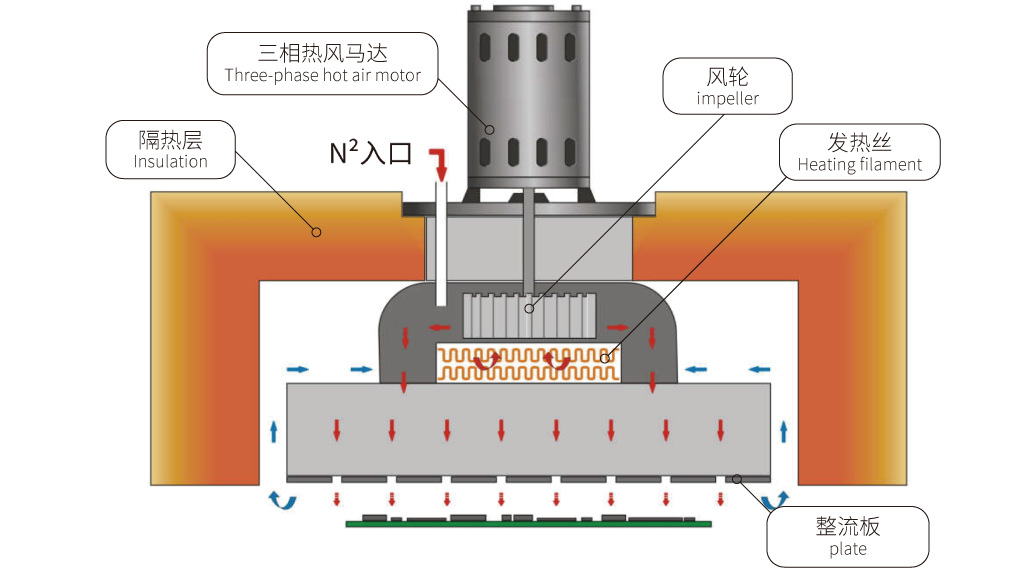

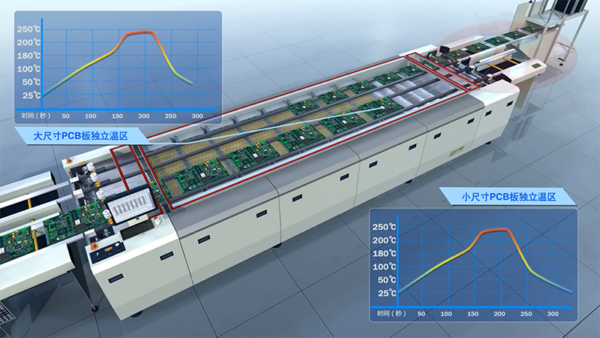

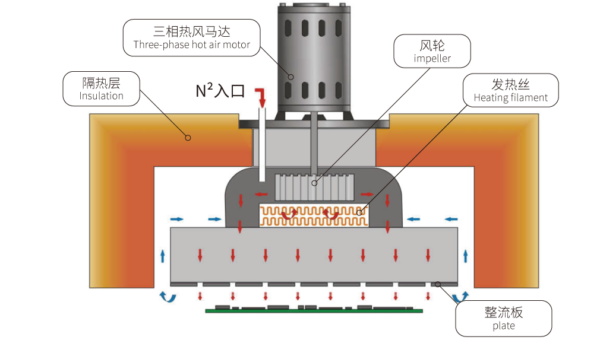

The oven uses controlled heat zones, typically with preheating, soaking, reflow, and cooling stages, to create optimal conditions for soldering. Hot air is circulated within the oven to evenly heat the PCB and its components, ensuring consistent soldering results across the board.

What Temperature is Hot Air Reflow?

The temperature in a hot air reflow oven varies depending on the solder paste and components used. However, the typical temperature range for lead-free soldering (commonly used due to RoHS compliance) is 220°C to 260°C (428°F to 500°F). For traditional lead-based solder, the range is slightly lower, around 180°C to 240°C (356°F to 464°F).

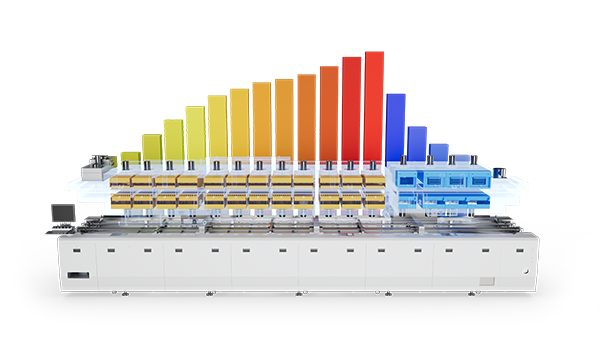

The heating profile in a reflow oven is divided into several stages:

- Preheating Stage: Gradually increase the temperature to avoid thermal shock to components. This phase typically lasts 60-120 seconds and reaches around 150°C to 180°C.

- Soaking Stage: Maintains a stable temperature to activate flux and remove contaminants. The soak zone hovers between 180°C and 200°C for about 60-90 seconds.

- Reflow Stage: Peaks at the solder paste’s melting temperature. This is the critical stage, ensuring that the solder adheres properly to create strong connections.

- Cooling Stage: Rapidly cools the board to solidify the solder joints, preventing defects like cracks or voids.

What Does RoHS Mean on Solder?

RoHS stands for Restriction of Hazardous Substances, a European Union directive aimed at reducing harmful materials in electronic products. Specifically, it limits the use of substances like lead, mercury, cadmium, and hexavalent chromium.

In the context of soldering, RoHS compliance means using lead-free solder, which typically contains a mixture of tin, silver, and copper. Lead-free soldering requires higher reflow temperatures compared to traditional lead-based soldering. This shift ensures a safer manufacturing process and reduces the environmental impact of electronic waste.

Advantages of Using a Hot Air Reflow Oven

- Uniform Heating: Ensures even heat distribution across the PCB for consistent soldering results.

- Versatility: Compatible with a range of solder paste types, including both lead-free and lead-based varieties.

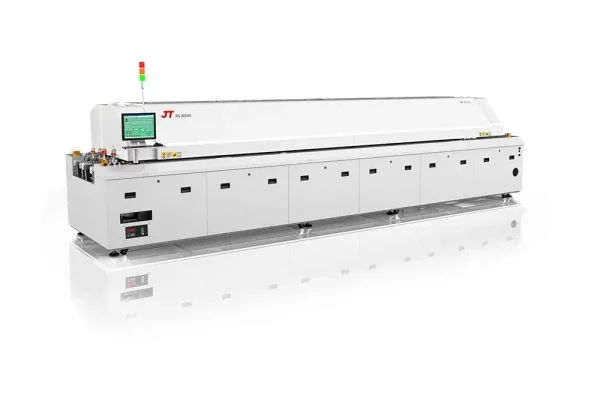

- Scalability: Ideal for both small-scale and high-volume production runs.

- Decreased Human Involvement: Automates the soldering procedure, minimizing the likelihood of operator errors.

Conclusion

Hot air reflow ovens play a vital role in contemporary electronics manufacturing. They provide a controlled environment for soldering components, ensuring precision and efficiency. With the increasing adoption of RoHS-compliant practices, these ovens have become even more critical in creating environmentally friendly electronic devices.

Understanding the reflow process, temperature ranges and RoHS standards helps manufacturers produce reliable and durable electronics while minimizing environmental impact. Learn a/, mm bout JT hot air reflow ovens. Investing in a high-quality hot air reflow oven is an important step in achieving professional-grade results.