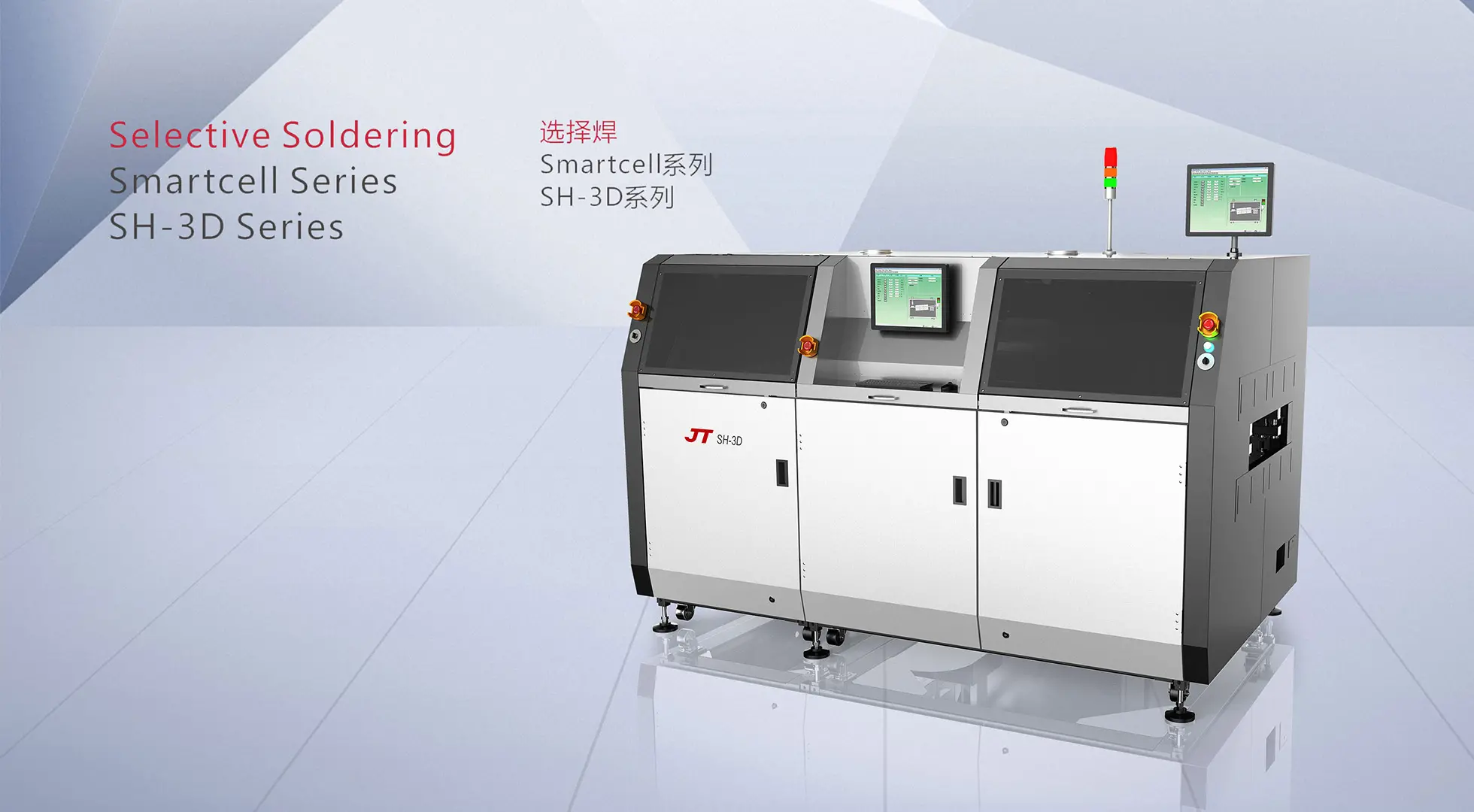

High-Quality selective soldering machine supplier and manufacturer maintaining the best industry standards and all safety features. Our machines follow all the electrical and health standards. On top

Best Selective Soldering Machine With Precise and High-Efficient

Introduction: In PCB (Printed Circuit Board) assembly, selective soldering is one of the most important processes and should be done in a proper way, otherwise solder joint defects will occur, which will directly affect the performance of the finished product. At the same time, it has to be precise and accurate so that it doesn’t damage any onboard SMD or Through Hole components. Selective soldering is one of the most used and effective methods of attaching components in PCB without any error. From the name, it is explainable that selective soldering denotes a kind of soldering process where only specific numbers of components get soldered on the PCB (which is determined by the designer or operator). In another name, it is also known as “Selective Wave Soldering”. Several major parts are needed in a selective soldering machine and by focusing on them the efficiency can be raised much higher. They are:

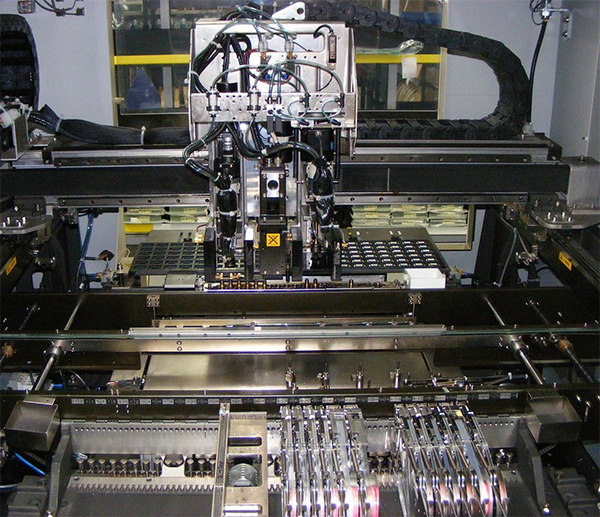

- Conveyer roller:A dis conveyer is used to transport the PCBs through necessary channels for the selective soldering process. This conveyor roller’s speed should be transport independently.

Spray Module: Flux is very helpful for intensifying the activity of the PCB board, the flux only need to be sprayed to the pcb parts that need to be solder. Our machine use the drop jet fluxer programmable in X and Y axis, Point-to-point jetting saves a lot of cost

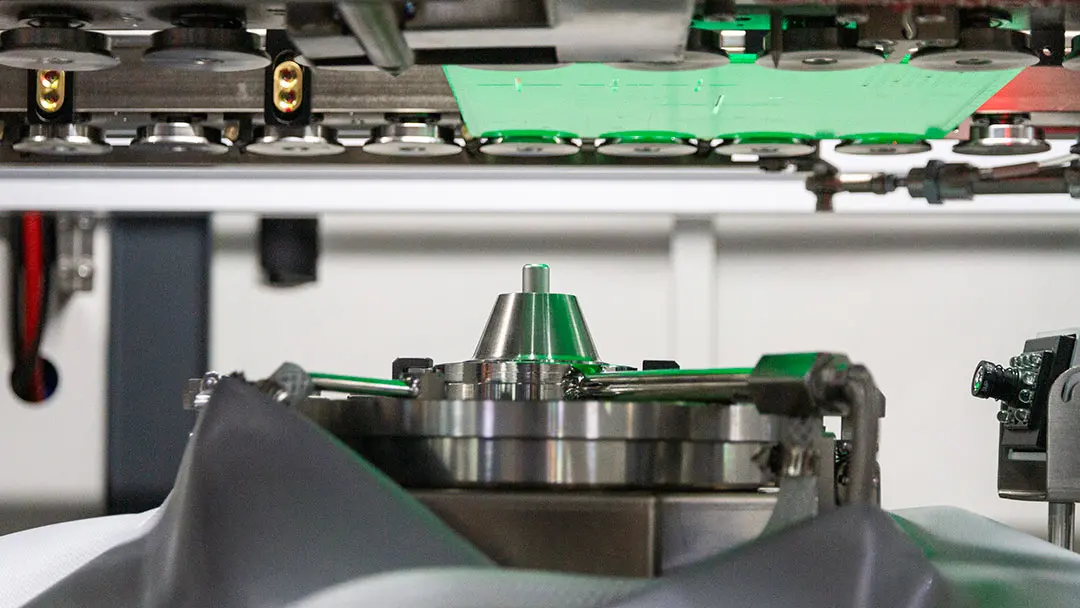

- Nozzle:By using a nozzle that applies a soldering wave to the specific location of the PCB to apply the soldering material. The operation and quality of the nozzle should be so precise and have to be stable so that it doesn’t cause disturbance to other components when soldering in a specific place. In JT , we ensure the best quality of the nozzle.

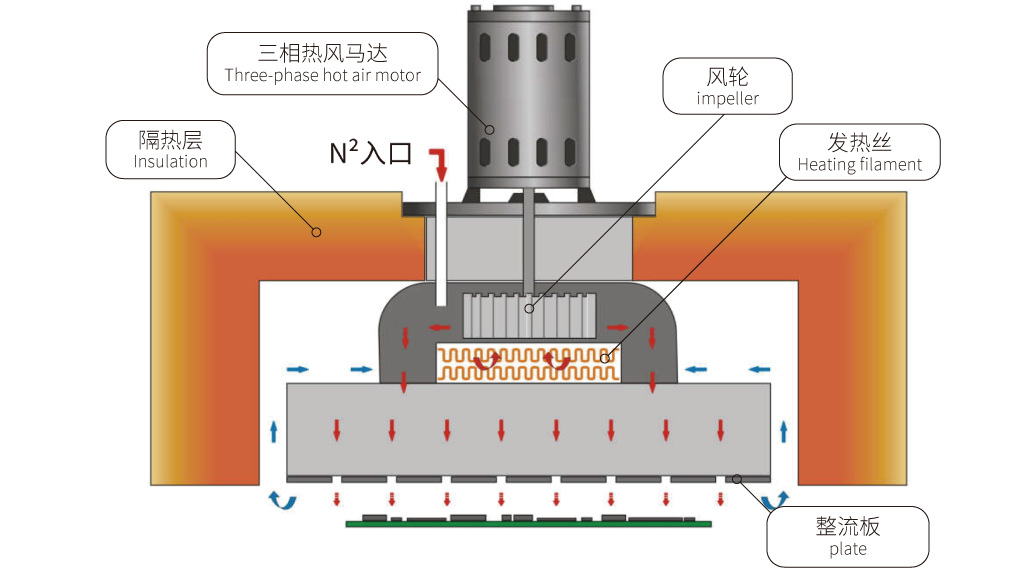

- Pre-heater:All the PCBs visit the pre-heater and get heated to a certain amount of temperature to meet the selective soldering process requirement. Our engineers always make sure to program the machine in such a way so that no electrical hazard occurs due to the heating environment. Also, in our machine, we use bottom InfraRed and top hot air which improves heating efficiency and keeps the temperature uniform.

- Soldering module: Dual pot platfrom, soldering at the same time, the nozzle can be moved by X Y and Z axis, ensure the accuracy and precision of soldering.

- Control and monitoring:Our designers and R&Dteam make the best user-friendly solution for the selective soldering system which can be operated both in English and Chinese language. The selective soldering data can be imported in both Gerber and Image format. And for monitoring the inside process we have provided a CCD sensor camera which allows the operator to surveillance the current scenario so that they can take steps if necessary.

What are the Advantages of using a selective soldering machine over a traditional system?

Except for the human labor error or man-do, there are a few other errors that get solved when using a selective soldering machine, which are:

- Reduce soldering time in a much more effective way

- Decreases errors at a surprising rate which increases production pass rate

- Much precise operation

- Cut costs than other traditional systems

- Reduce PCB damage risks that are present in Wave Soldering

We have several models of selective soldering machines depending on the operation type. They can be used both in the mini production line and large quantity production units. Our selective soldering machine can work for both SMT (Surface Mount Technology) and Through-Hole Technology.

In Shenzhen JT Automation Equipment Co., Ltd, we are always focused on customer satisfaction. We have numerous reputed clients and we are a proud supplier of selective soldering machines. We can also customize products depending on your need. Please contact us if you have any queries. Visit our website to know more about us.