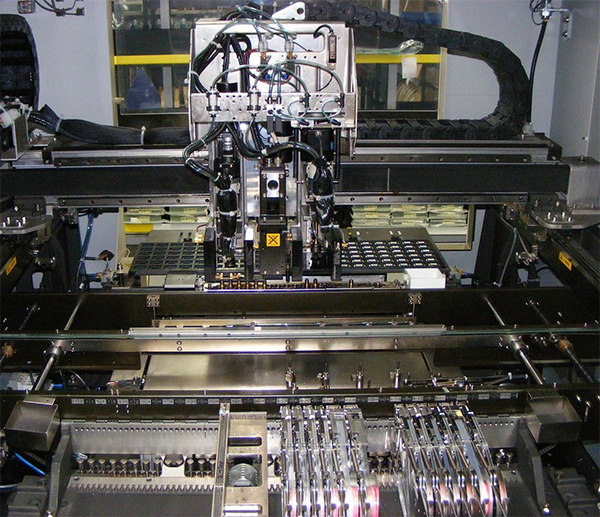

A wave soldering machine is a distinctive machine used in the electronic manufacturing industry. It mainly works to solder through-hole components on printed boards (PCBs). Far from other wave soldering machines, to connect parts with the PCB, wave soldering uses a molten wave of solder. This way, it makes the soldering process efficient and reliable.

If you want many functions to make your soldering process smooth and efficient in one location, then look at the Jt wave soldering machine. This wave soldering machine has several distinct features that make it stand out from other wave soldering machines available on the market.

In this post, you’ll explore the Jt wave soldering machine’s unique features and how they contribute to effective and efficient soldering. So, let’s dive in and explore the features of the Jt soldering machine.

What Unique Features of Jt Wave Soldering Machine Make it Different From Other Machines?

-Versatility for any Wave Soldering Application

Jt wave soldering machines can be composed of dual waves to assist through-hole, surface mount, and mixed-technology assemblies. Its module design is suitable for both SMT and THT component soldering processes. In addition, non-SMT applications can deactivate the chip wave through the user interface. With the addition of an oscillating wave option, the chip wave can aid in hole filling and ease the soldering process for all technologies.

-Highest Transportation Capacity

The maximum transport capacity of the JT wave soldering machine is 60 kg. The higher transportation carrying capacity and more stable speed are due to the innovative transportation chain structure.

-High-Temperature Pumps and Motors

It contains high-temperature pumps, and the temperature controls for top and bottom preheating are independent. Moreover, its infrared heating improves heating efficiency and maintains temperature uniformity throughout the soldering process. Its highly efficient motors ensure precise wave height and uniformity.

-Fluxing System

With the assistance of a stepping motor, the nozzle can rotate in a dual axis, such as the X and Y axes, with accurate positioning.

-External spray fluxing system

External spray flux is independent and mounted to X-axis. It ensures safety, high efficiency, and atomization uniformity due to the imported precision nozzle.

-Internal spray fluxing system

An automatic internal spray fluxing system mounted on the Y-axis has a precise spray nozzle assembly that guarantees uniform spraying and saves flux consumption.

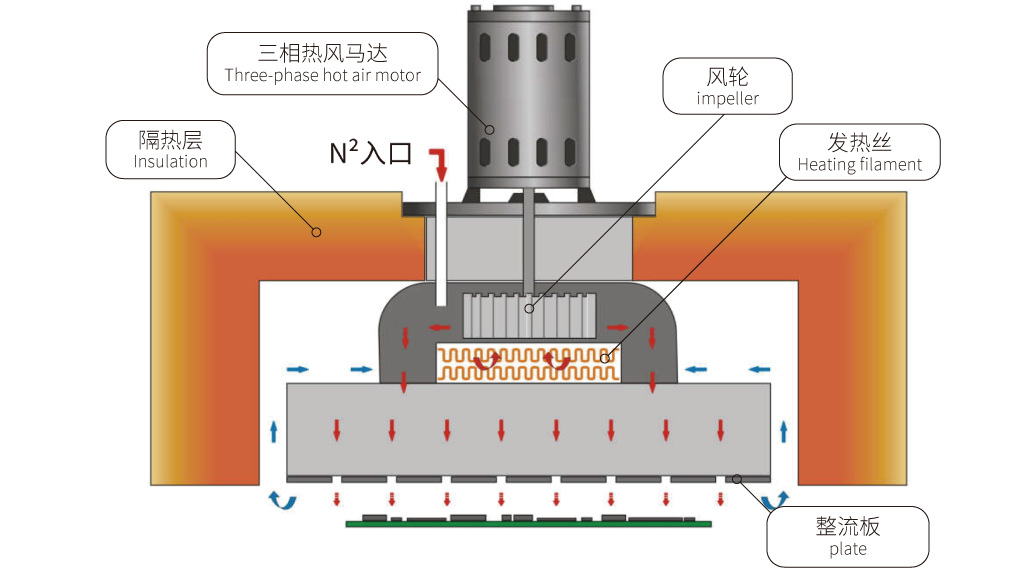

-Nitrogen System for Wave Soldering

In wave soldering, the nitrogen generates an inert atmosphere to minimize solder oxidation. N2 involvement saves solder material and reduces maintenance requirements. Moreover, it improves the solder wetting and ensures the quality of formed solder joints.

Conclusion

After exploring the unique features of the Jt wave soldering machine, it is clear that it offers several advantages over other types. This wave soldering machine is designed to provide reliable, cost-effective, and high-quality soldering results with minimal defects to electronic components.

Overall, the Jt wave soldering machine’s distinctive characteristics make it an ideal choice for those seeking an efficient, reliable, high-quality soldering solution for their electronic manufacturing needs.

If you’re looking for that type of wave soldering machine, then contact us.